Abengoa

Abengoa

Annual Report 2013

- Corporate Social Responsibility

- Environment

- Abengoa’s main environmental indicators

To calculate Abengoa’s environmental indicators 3 , we consolidated all of the data from all its work centres, the activities associated with them and all the projects managed by Abengoa.

Raw material

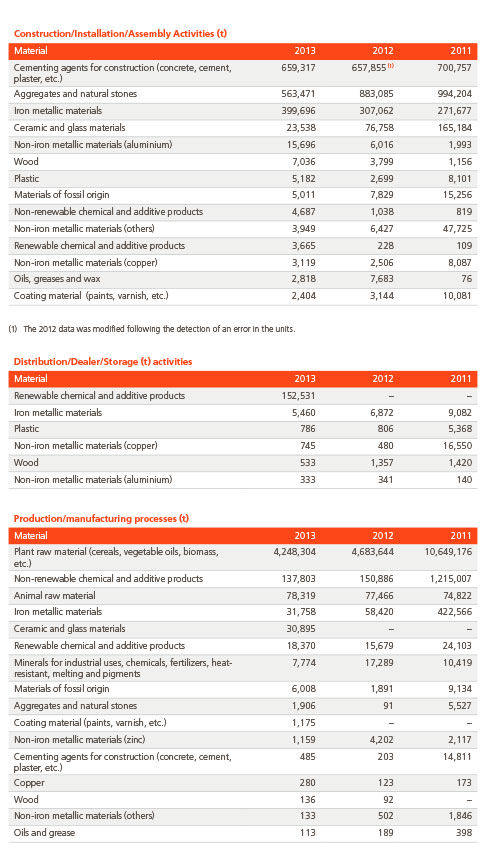

The optimization in the consumption of materials, the reduction in the use of natural resources and the increase in the efficiency from the economic stand point, constitute a significant part of Abengoa’s commitment to sustainability.

Below are the main materials used by the company, classified based on activities.

The variation n the use of some raw materials in construction-related activities is determined by the number of projects, their type and current execution phase.

For example, the inclusion of three plants of the solar business group (builder of mirrors for solar plants) into Abengoa’s consolidation perimeter is the motivating factor behind the reporting of glass, ceramic and coating materials, in the activity, for the first time, —Production/Manufacturing Processes.

The drop in minerals in this activity is due to a change in information reporting criteria.

In its quest for new renewable energy sources, in 2013 Abengoa opened an urban solid waste recycling plant to produce ethanol using W2B 4 technology. The plant has so far consumed 928 t of waste.

Abengoa also analysed the recovered material consumption ratio, which contributes to the reduction in the demand for virgin material and the total cost of the processes. In 2013, 2 % of the materials used were recovered.

Energy

The growing energy demand forces the search for new solutions to forestall the exhaustion of resources while reducing environmental impacts.

That is why Abengoa promotes facilities that convert renewable sources of energy into electricity and biofuels, laying transmission lines that support the electric systems and encourages responsible consumption based on autonomy, in the diversification of energy and the introduction of efficiency measures that expands the processes and activities of the company.

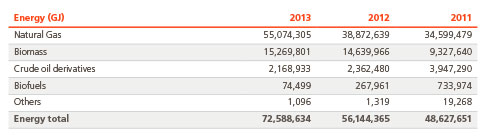

Below is a detail of direct energy consumption linked to Abengoa’s production and construction processes, classified by fuel type.

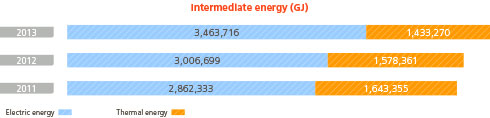

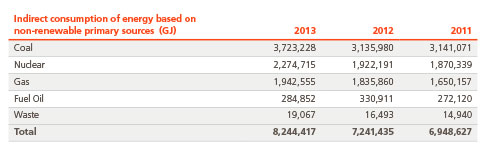

Also, the facilities, work centres and projects directly executed by Abengoa consume intermediate energy in the form of electricity and thermal energy based on the graph below.

In keeping with its commitment to clean technologies, Abengoa’s consumption of electricity from renewable energies reached 21 % in 2013.

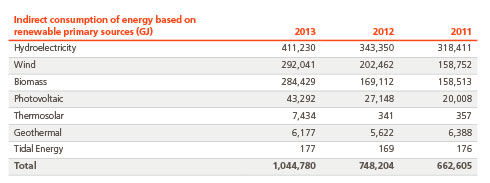

Translating this electricity consumption into the renewable primary sources employed in its generation, according to the data obtained from the International Energy Agency (IEA), it happens that the highest consumption is from hydro energy, followed by wind and then biomass.

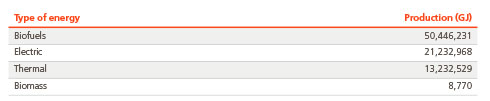

Abengoa is not only an energy consumer, A great part of its activities is devoted to the production of renewable energies to help reduce the environmental impact that the growing energy demand is generating. In 2013 its energy production amounted to 84,920,498 GJ, broken down as follows:

21 % of the electric energy produced came from solar.

Another fundamental pillar in the implementation of Abengoa’s policies and the attainment of its sustainability targets is the introduction of measures that help to reduce energy consumption with regards to the increase in the company’s activities. Thus, in 2013 the company implemented various initiatives aimed at improving energy efficiency, among which are:

- Introduction of an energy efficiency management system based on ISO 50001 Standards. This system was certified by an external party at the bioethanol plant in A Coruña (Spain).

- Modification of the biofuel distillery facilities in Salamanca (Spain) to improve the utilization of residual heat.

- Improvements Abengoa’s main offices in Buenos Aires (Argentina), which included procurement of energy-saving printers, movement sensors and energy saving lighting systems.

Water

Captures of any water system may affect the environment due to water table lowering, the reduction in the volume of water available for consumption, or may cause any other alteration of the ecosystem’s equilibrium. Such changes cause severe consequences, both economic as well as social.

Abengoa identifies the origins of its water captures and up till now it has not detected any source that is included in the Ramsar list of Wetlands, which may be considered especially sensitive or that the volume of its annual consumption amounts to more than 5 %.

As its priority, Abengoa’s sustainability policy establishes the rational use of resources, the prevention and reduction of repercussions on the environment. Therefore, regarding water resources, the targets sort, in addition to monitoring the origin, are to minimize the usage, reuse for activities in which potability is not important and the capture of alternatives to that used by the human consumption supply networks.

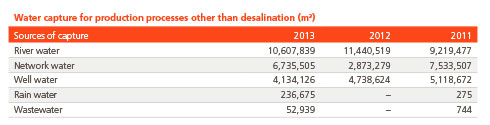

The increase in grid water withdrawal with respect to the previous year is mainly attributed to the operational start-up in 2013 of a cogeneration plant in Mexico.

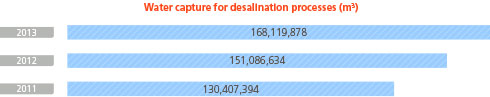

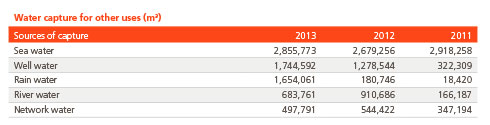

Below are the water captures in 2013 for processes other than the preceding, like refrigeration, watering, sanitation, etc.

Reused water amounted to 9 % of the total volume captured by Abengoa.

Like in energy consumption, Abengoa is not only a water consumer but also a generator of potable water in geographical areas that suffer its scarcity. In 2013 the company generated 50,078,135 m3 of potable water.

Spillage and Dumping

Abengoa is well aware of the fact that a good environmental management requires the correct treatment of effluents or waste process water in its facilities in order to minimize the impact on the environment.

Thus, in companies in which the state of the water used is negatively altered due to the activities carried out, such water is subject to adequate treatment before being dumped into public water channels or sewer networks. Every dumping is therefore authorized and monitored by the competent entities to ensure its conformity.

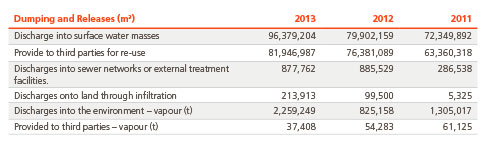

The table below shows the amount of discharges and dumping releases during the activities of Abengoa.

The rise in discharges through infiltration into land with regards to previous year was because the four thermosolar platforms in Spain functioned all year round in 2013 while in 2012 they only started functioning during the second half.

Along these lines, one of the initiatives aimed at improving control over water discharges into the atmosphere was introduced at the biofuel plant in Salamanca (Spain), and involves cleaning the final segment of the dumping line to eliminate solid organic material that may be was also cleaned to enable clear observation.

On the aspect of spillages, and even though Abengoa makes every systematic efforts to prevent it, in 2013, according to the company’s information channels, a total of 133 spillages occurred, and the cost of reparation amounted to € 81,243. At any rate, spillages were not significant, and in most cases, the environment and the atmosphere were not affected.

Among the measures put in place to combat spillages and to prevent leakages, the thermosolar platform in Extremadura (Spain) implemented an initiative that entailed replacing nitrogen with helium as the gas used to inert steam or thermal oil (HTF) loops and circuits. Thanks to the smallness in the size of helium molecule, this measure is aimed at improving leakage identification at circuit edges before the performance of the final test loops with HFT.

Waste

Abengoa gears the management of its daily activities towards minimizing the generation of waste, making recycling and reuse a priority over other options and recovered energy over dumping. Generated waste monitoring enables the evaluation of reduction and improvement of efficiency in production processes.

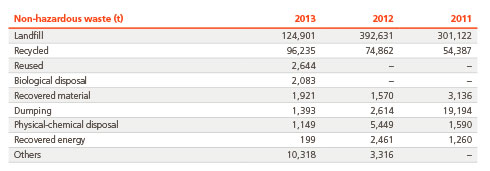

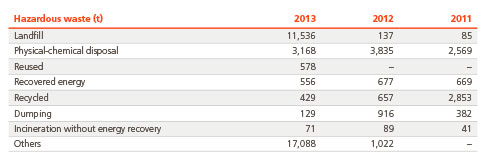

Below are the most significant wastes that Abengoa produced in its activities based on the final destination, separated by whether hazardous or not.

In 2013 non-hazardous waste generation went down by more than 50 % with regards to 2012. This decrease occurred primarily as the result of a change in criteria applied to assessment of these wastes given that a significant quantity thereof are currently valorized and are not considered wastes.

On the other hand, the value of generating the most significant hazardous waste has risen. This is mainly on new projects that have entered the execution phase, new plants that have commenced operations (such as Solana, in the US), the creation of new companies that have begun to report their environmental data (for example, the three mirror manufacturing plants) and improvements made in identifying environmental data at newly created plants.

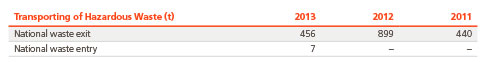

Inappropriately transporting hazardous wastes, especially to countries that lack national regulations and infrastructures for treating them, may be dangerous to both human as well as to environmental health. Abengoa therefore ensures that this activity is performed by authorized handlers and it investigates the destination of its waste. The table below shows the main highlights associated with the transporting of hazardous waste.

Emissions

In-depth knowledge of emissions enables Abengoa to establish reduction targets and assess the progress of its reduction measures.

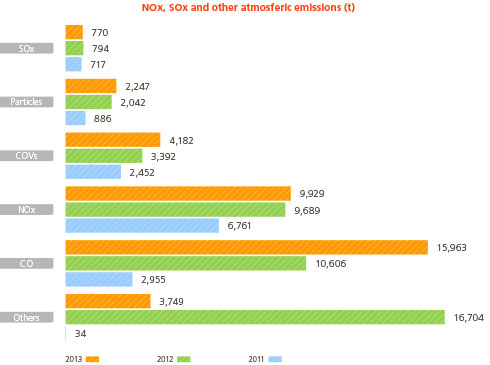

Emissions of NOx, SOx, CO, COVs, particles and substances that destroy the ozone layer

Abengoa performs a follow-up on the emissions of substances that may destroy the ozone layer. The amount registered for such kinds of substances was 2.47 t in 2013.

The increase in the amount of emissions of substances that reduce the ozone layer for 2013 is related to a change in the method of reporting.

Below is a detail of emissions registered for NOx, SOx, CO, COVs and particles based on weight.

In 2013, according to Abengoa’s information channels, there were no entries of incidents relating to the emissions of these kinds of substances into the atmosphere.

Inventory of Green House Gas Effect

In 2008 Abengoa created its GHG Inventory which is managed using an internal tool integrated into the Integrated Sustainability Management System (ISMS). At present, the level of maturity of the GHG emissions management system has enabled the company to lay out plans for reducing the emissions and to develop the labelling of emissions of products and services 5.

Abengoa’s emissions management system is externally verified in accordance with the ISO 14064 Standard and the information below is consistent with the quantitative information included in the GHG Emissions Report for 2013 which was verified by Aenor.

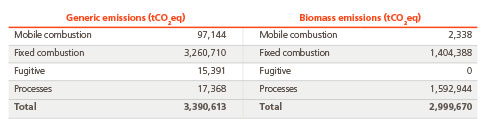

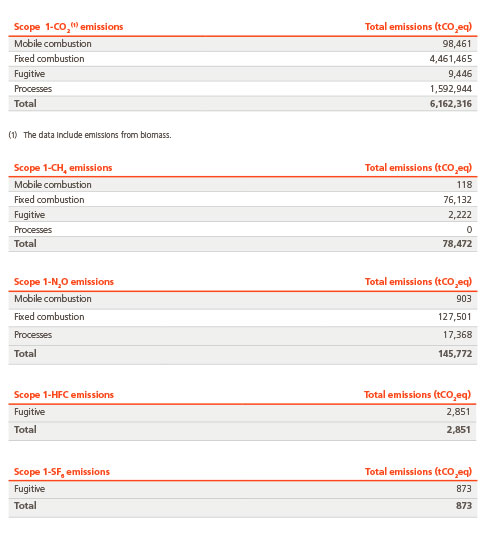

Scope 1 emissions

Below is a detail of GHG emissions derived from own sources or sources controlled by Abengoa, broken down by source type, distinguishing between those associated with biomass and those associated with other production processes.

Scope 1 emissions broken down by GHG type

No PFC or NF3 emissions sources were identified.

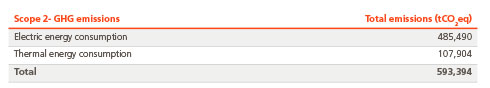

Scope 2 emissions

Electricity and thermal energy emissions generated by other companies and acquired and consumed by Abengoa through out its entire activities.

Scope 3 emissions

Indirect emissions that are consequence of the company’s activities, but that emanate from sources that are not of the company itself or that are not under its control.

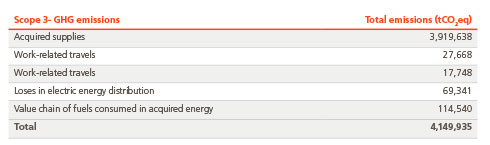

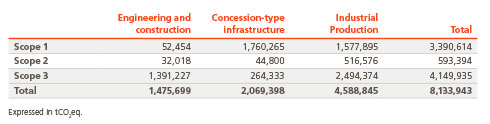

GHG Emissions by Activity Segment

Given that Abengoa structures its business around three activity areas —Industrial production, Concession Infrastructure and Engineering and Construction—, emissions data are presented for each of these segments in each of the three scopes, for the 2013 financial year:

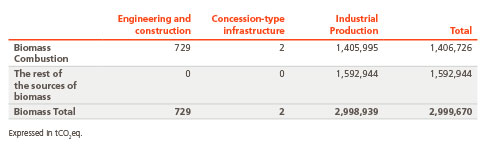

In addition, biomass emissions are as follows:

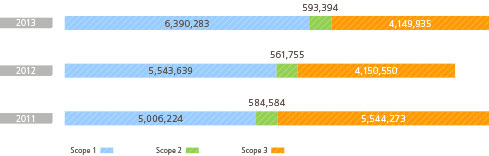

Record of GHG emissions

Expressed in tCO2eq.

Reduction of GHG emissions

Abengoa promotes the annual design of emissions reduction plans for all the companies within the organization. Since 2013, These reduction plans have been optimized and executed as directed actions, based on the requirements of ISO 14064-1.

Below are the most important initiatives undertaken in 2013:

- Optimization of the system for capturing CO2 generated during the process of producing bioethanol. The company captured 76,200 tCO2eq at the bioethanol plant in Rotterdam (the Netherlands) and 29,485 tCO2eq at the bioethanol plant in France for subsequent sale thereof to ther companies.

- Reduction of 1.58 % in sugar cane pulp humidity during the bioethanol production process at São João (Brazil). This humidity reduction marks an increase in energy generation capacity because much more steam is produced for each ton of sugar cane pulp used. The total reduction attained in 2013 was 9,341 tCO2eq.

- Improving the performance of the combined-cycle plant in Hassi-Rmel (Algeria) in order to increase the energy delivered while maintaining the plant’s gas consumption at normal operating levels. This effort lowered specific consumption and prevented the generation of 45,340 tCO2eq.

- Fitting of electric lines to power one of the offices of R&D and innovation company in Sanlúcar la Mayor (Seville, Spain). This measure prevented the emission of 1.703 tCO2eq.

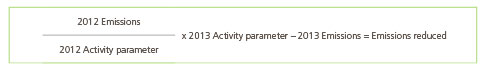

The correct evaluation of the progress of GHG emissions requires that the variations in the activities of the company be taken into consideration in the analysis. Thus, Abengoa evaluates the management of emissions using a formula that yields GHG emissions variations in theory for one year in comparison to the previous:

The first step to analysing it is to determine the parameter of activity that best defines the company’s endeavours. Once said parameter is identified the calculations must be based on the following steps:

- Compare the 2012 emissions with the activity parameter data established at the close of the 2012 financial year, and obtain a ration of emissions/parameter for 2012.

- Then extrapolate the situation of 2012 to that of 2013 and obtain the GHG emissions that the company would have obtained in theory if its activity had not varied from one year to another.

- Once that is done, compare the supposed 2013 emissions with the actual emissions of said year and obtain the supposed variations (increase or decrease) in emissions for one year as regards another.

The heterogeneous nature of the organization’s businesses led Abengoa to select sales as an activity parameter performed in all operations. The use of the aforementioned formula shows that the 2013 reduction obtained in theory in comparison to that of 2012 reaches 818,754 tCO2eq.

Biodiversity Management

In the execution of its activities, Abengoa encourages biodiversity conservation through the management, prevention and restoration in order to minimize the impact that its activities may bear on the environment. This includes from reforestation plans to strategies focused on the protection of flora and fauna species or to the imparting of trainings to prevent forest fires.

In line with the above, Abengoa performs environmental impact studies and tasks that entail monitoring of activities carried out in terrains adjacent to or within protected areas, identifying species affected and assessing the impacts derived thereof.

Abengoa owns companies in Brazil, France, Poland, South Africa and Spain, located in the surroundings of protected areas. Nevertheless, according to the information reported in 2013 in the information channels, none of them bear any high impact on the ecosystems.

Among the most significant are projects involving solar construction in South Africa by one of the engineering and construction affiliates, which affect a protected area of 675 hectares, and electrical power transmission line construction projects in Brazil, which affect a protected area of 537.38 hectares.

In both cases, protection measures have been introduced for the protected areas. The South African situation will include efforts to delimit and restrict access to said areas. The brazilian projects also implemented biodiversity conservation-related initiatives, like sowing in and maintaining the affected areas for environmental restoration, an endeavour that meant an investment of € 80,217.

Likewise, one of the engineering and construction affiliates in Mexico is involved in some environment-related actions in the construction of the Centro Morelos (Mexico) combined-cycle plant, in which it follows-up on the fauna relocation program introduced last year, especially regarding the endemic species in the Predio area of the Plant, covering a surface area of 45.64 hectares.

And, finally, worth highlighting are the biodiversity protection activities undertaken at the bioethanol plant in Indiana (US), where a range of initiatives amounting to € 103,849, have been implemented to preserve forest areas.

As part of the strategies and actions introduced and planned for managing the impacts being borne on the biodiversity, as reported by the information channels of Abengoa, those of the electricity energy transmission lines construction project of Abengoa Brazil should be highlighted. To identify possible environmental impacts and adopt measures that may enable their prevention and mitigation, these initiatives entail preparing inventories and studies of what are affected in fauna populations and in environmental monitoring programs for the follow-up and control of the fauna and flora, an investment that has cost € 910,746.

Albeit on a much smaller scale at two of the Extremadura Solar Complex plants (Spain) have also introduced initiatives involving reforestation programs and perimeter fencing to protect vegetation.

Also worthy of mention is the topsoil initiative implemented at the Khi Solar One plant (South Africa), consisting of the transformation of organic vegetable waste through a natural process, recovering and utilizing the waste to regenerate soil affected by the project.

Products, Services and Transportation

Environmental impacts derived from utilization and end of useful life of products and services have today acquired importance that is equal to or greater than impacts derived from the production phase, something that is becoming an even greater environmental challenge by the day.

Their nature and type has not enabled the identification of initiatives for mitigating the environmental impacts of the products and services sold and placed on the market which are recovered at the end of their useful life, and neither has specific measures been introduced to reduce the possible impacts of these products and services.

Nevertheless, regarding the recovery of products and packages placed on the market, in 2013 the company recovered 36 t of plastic packaging used in marketing the sugar produced by the cogeneration plant in São Luiz (Brazil).

In 2013 Abengoa’s information systems did not identify any significant impacts derived from the transportation of products and other goods and materials used for the activities of the organization or for the transporting of its personnel.

Regarding the latter aspect, a series of actions were taken to ensure the reduction of emissions in 2013:

- Sensitization campaigns to promote the use of public transports to and from work centres.

- Bus shuttle services for employees of specific work centres with significant amount of workers.

- Meetings held using the tool know as Gotomeeting.

- Efficient driving courses.

- Use of the vehicle-sharing system or Carpooling.

Noises

Acoustic pollution is the excess noise that alters the normal environmental conditions of a specific area. If not properly controlled, this kind of pollution can cause severe damage to the life quality of people.

In 2013, according to information registered in the information channels of Abengoa, no incidents occurred and no initiatives were started in noise-related matters.

Odours

The concept of odour or smell pollution has acquired special importance over the past years. Not being a risk to the health of the population, this kind of pollution generates discomfort that may influence the life quality of people.

In 2013, the following initiatives were developed in the field of smells:

The bioethanol plant in A Coruña (Spain) concluded a study of smells that began in 2012 which was aimed at determining odours and their distribution throughout the plant. The initial phases entailed the study of the emission points, performing olfactometric sampling and analysis, and the final phase involved the odour dispersion simulation.

The cogeneration plant in Jaén (Spain) installed an ultrafiltration system at the exit of its treatment plant to improve the quality of the water channelled to the cooling towers and, thereby reducing unpleasant odors.

Series of complaints were filed in relation to the emission of smells at the bioethanol plant in Rotterdam (the Netherlands) in 2013. Although the levels were not significant, a regenerative thermal oxidizer was installed to eliminate the odours. The company also implemented communication campaigns with the local media to inform surrounding communities on the operational start-up of the facility. The two initiatives amounted to an investment of € 3.4 M.

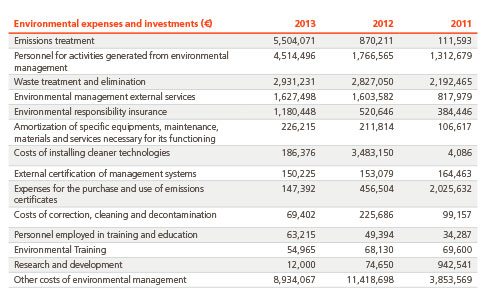

Environmental expenses and investments

The evaluation of the expenses derived from environmental mitigation and protection permits Abengoa to evaluate the efficiency of its environmental initiatives and to better focus its environmental investments.

Below is a breakdown of the 2013 environmental expenses and investments.

Investing in the development of initiatives and projects for environmental protection is Abengoa’s priority. This is proven by the fact that though there are reductions in some items motivated by the state of some of the projects, the investments continue with regards to last year.

In 2013 a fine of € 11,500 was imposed on the company in relation to the reporting of CO2 emissions at the bioethanol plant in Rotterdam (the Netherlands).

Note 3: All indicators were calculated using the specific measurement and calculation protocol for the purpose of homogenizing the application criteria.

Note 4: For more information see the chapter “Innovative technology solutions for sustainability” or see the Activities Report (Volume I of Abengoa’s 2013 Annual Report).

Note 5: For more information on labelling of CO2 see the chapter on “Customers”.

Photograph taken by Bernabé Lugo Puerto, for the fifth edition of the photography competition on sustainable development.

© 2013 Abengoa. All rights reserved