Abengoa

Abengoa

Annual Report 2010

- Activities

- Business Units Activities

- Solar

- Our Activities

Our Activities

Abengoa Solar’s business model is based on three lines of activity:

- The development of CSP and PV plants:

This area includes activities such as identifying ideal locations for solar plants, obtaining the necessary permits, negotiating funding and construction agreements, and, if deemed necessary, identifying potential partners and reaching agreements with them. Furthermore, Abengoa Solar provides support in the engineering and turnkey construction of plants, while supervising the progress of the construction phase. - Sale of energy from, and operation and maintenance of, those plants.

- Development of new technologies through R&D, and the manufacture and sale of key components for CSP and PV plants.

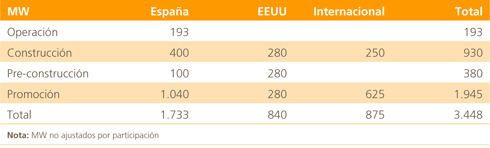

Abengoa Solar’s portfolio of projects is classified according to the degree of maturity of development. There are four project phases that are usually classified as follows:

- Development: primarily encompasses selecting a location, securing land and evaluating solar resources; administrative processing and applying for licenses, permits and authorizations; processing of the grid connection and connection infrastructure.

- Pre-construction: this stage includes activities to secure funding for the plants which, in addition to having rights to the land, permits, authorizations and licenses, also meet the requirements entitling them to receive certain revenues (listing in the pre-allocation registry, or approval of a power purchase agreement by the state public utility commission, in the case of the United States).

- Construction: includes initial physical construction of the facilities, engineering and construction supervision and processing of permits corresponding to this phase, as well as support in starting up the facilities.

- Operation: includes taking operational control of the plant following construction, the evacuation and sale of energy, and the operation and maintenance of the plants.

Plants in Operation

Abengoa Solar currently operates a total of 193 MW in Spain.

PS10

Particularly noteworthy is the solar field comprising 624 heliostats, each measuring 120 m2, concentrating solar radiation onto the receiver, which is located at the top of a 120 m tower.

Located at the Solúcar complex and with an installed capacity of 11 MW, it generates enough clean energy to meet the needs of 5,500 households, and prevents 6,700 t of CO2 emissions per year. The plant also has a storage system of almost one hour’s duration which enables it to experience temporary cloudy periods without having to be shut down and restarted. It was the world’s first solar power plant to incorporate a power storage system.

In June 2007, the plant passed its first operating tests, and since then it has continued to operate, delivering the expected results. Ever since its start-up, PS10 has proved the viability of the power tower concept and has also been an invaluable learning instrument for improving upon future power tower plants.

PS20

Launched in February 2009, this plant, located at the Solúcar complex, has benefited from Abengoa Solar’s experience in building and operating PS10. The plant incorporates a number of design and operational improvements, which have translated into greater efficiencies and lower parasitics during the nearly two years in which it has been operating. These enhancements include a more efficient receiver and a number of improvements to the control and operation systems and also to the thermal energy storage facility.

With an installed capacity of 20 MW, PS20 supplies power to10,000 households and reduces yearly CO2 emissions by 12,100 t. This second solar tower at the Solúcar complex comprises 1,255 heliostats designed by Abengoa Solar. Each heliostat measures 120 m2 and reflects the solar radiation onto a receiver located on the 165 m tower, thereby enabling the steam production required to generate electricity in the turbine.

Solnova 1, Solnova 3 y Solnova 4

During 2010, Abengoa Solar started the operation of the first three parabolic trough plants at the Solúcar complex: Solnova 1, Solnova 3 and Solnova 4, each with 50 MW of installed capacity. With the commissioning of Solnova 1, Abengoa Solar now operates plants using both commercial CSP technologies, tower and trough.

The trough technology concentrates solar radiation through high-precision curved mirrors onto a receiver tube containing a fluid flowing at high temperatures. The fluid allows the plant to generate steam, which is then sent to a turbine generator, where it expands to produce energy.

Each Solnova plant has 54,000 m2 of solar collectors, distributed over an area of 120 ha, enabling it to produce enough power to supply 26,000 households and to cut CO2 emissions by approximately 31,000 t. Each collector has 6 m in aperture and a surface area of close to 150 m2.

Solnova 1, Solnova 3 and Solnova 4 solar trough collector plants in operation at the Solúcar complex Seville

Solnova 1, Solnova 3 and Solnova 4 solar trough collector plants in operation at the Solúcar complex Seville

Sevilla PV

With an installed capacity of 1.2 MW, Sevilla PV was the world’s first commercial plant to utilize low-concentration PV technology. It has 154 solar trackers on a 12 ha plot at the Solúcar complex.

The plant can supply clean energy to 650 households, cutting yearly CO2 emissions by more than 1,800 t.

Copero PV

A 1 MW PV facility located on the site of Emasesa’s Wastewater Treatment Plant (WWTP) at El Copero, Seville. Emasesa and Abengoa Solar are 50 % co-owners of this PV plant.

Las Cabezas PV

A 5.7 MW PV plant with single-axis trackers located in an area of high solar radiation in the province of Seville.

Casaquemada PV

A 1.9 MW PV plant using dual-axis PV tracking technology, located at the Solúcar complex. It includes 100 kW of high-concentration heliostats.

Photovoltaic plant comprising conventional and high-concentration heliostats operating at the Solúcar complex in Seville

Photovoltaic plant comprising conventional and high-concentration heliostats operating at the Solúcar complex in Seville

Linares PV

A 1.9 MW PV plant with dual-axis trackers located in Jaen.

Industrial Facilities

Abengoa Solar develops designs and constructs small-, medium-, and large-scale customized facilities.

Industrial solar thermal facilities employ parabolic trough technology to generate thermal energy (heat and steam) for industrial processes. The main advantage of this technology is that it can be adapted to different needs, while also helping to cut CO2 emissions, since industry is one of the primary sources of greenhouse gas emissions.

Noteworthy in 2010 was the commissioning of three industrial solar thermal facilities:

- The solar thermal facility integrated into a Colorado coal-fired power plant owned by Xcel Energy, a public utility. This facility, which was brought into service in early 2010, increases the plant’s thermal efficiency while reducing CO2 emissions by cutting down on coal consumption.

- A new industrial solar thermal system was installed at the Englewood Correctional Institution in Colorado. This facility includes a storage tank that supplies hot water all day. The system supplies 50 % of the hot water consumed at the institution.

- The industrial solar thermal facility for the Palmas Altas buildings’ climate control system was placed in service, thus minimizing the electric power requirements of the complex, where Abengoa’s offices are located.

Industrial solar thermal facility for the climate control system at the Palmas Altas Campus

Industrial solar thermal facility for the climate control system at the Palmas Altas Campus

Plants under Construction

In 2010, Abengoa Solar commenced construction of most of the plants listed in the Spanish pre-allocation registry. Each of these plants will produce enough electricity to supply approximately 26,000 households and cut yearly CO2 emissions by more than 31,000 t.

Construction activities also got underway at the Solana facility in the US, and at the Shams site in Abu Dhabi.

Ecija Solar Complex

In order to construct and operate the two 50 MW plants, Abengoa Solar entered into a 50 %-50 % alliance with E.ON, and has secured non-recourse debt financing totaling €310 M. With over 88,000 employees, E.ON is today one of the world’s major privately owned gas and electricity companies.

The construction work is progressing according to plan, and both plants are due to enter into service in 2011. The main work at these two plants currently involves finishing the installation of the mirrors in the solar field.

El Carpio Solar Complex

For the construction and operation of two 50 MW parabolic trough plants, Abengoa Solar entered into an alliance with JGC whereby Abengoa Solar holds a 74 % interest, having secured non-recourse debt financing totaling approximately €350 M.

Founded in 1928, JGC Corporation remains a leading engineering company today. It currently offers a broad range of services in planning, design, engineering, construction, and delivery of facilities in sectors such as hydrocarbons, new energies and nuclear energy, and it has a proven track record in more than 20,000 projects in more than 70 countries.

Construction of these two plants got underway in summer 2010 and is advancing according to plan, with current work focusing on the foundations for the solar field.

Extremadura Solar Complex

Two of the four 50 MW plants comprising the Extremadura solar complex are in the construction phase. For the construction and operation of these two plants, a collaboration agreement was signed with Itochu, a leading Japanese holding company with more than 100 years of experience, a proven track record, and a presence in 74 countries.

The construction of these two plants is progressing according to plan.

Castilla-La Mancha Solar Complex

Abengoa Solar is building two 50 MW parabolic trough plants in the province of Ciudad Real (Castilla La Mancha).

The initial construction phase has been completed and work on the foundations of the power islands of both plants is nearing completion.

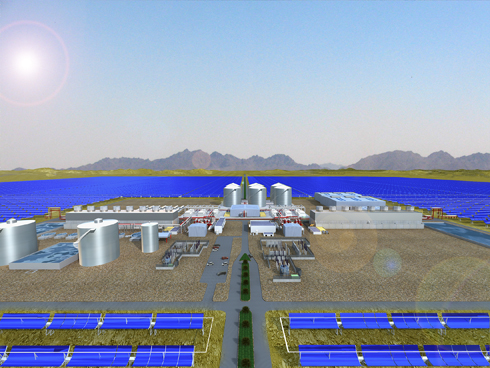

Solana

Located approximately 110 km southwest of Phoenix, Arizona, Solana is one of the world’s largest CSP plants under construction, with a gross installed capacity of 280 MW (250 MW net) comprising cutting-edge parabolic trough technology. Solana will produce enough power to supply 70,000 US.

households, slashing yearly CO2 emissions by 475,000 t. The energy will be sold to Arizona Public Service, the state’s largest electric utility, through a 25-year power purchase agreement.

Solana will incorporate six hours of storage capacity through molten salt technology, enabling it to generate energy during cloudy periods and after the sun sets. This storage capacity will enable Solana to generate enough electricity to meet peak evening demand in summer.

Abengoa Solar has received an FLG from the US. government of $1,450 M, enough to complete financing for the project and commence construction. Earthwork and work on the foundations of the assembly facility are currently under way.

The construction and operation of Solana will bring huge benefits for the people of Arizona, including the creation of 1,600-1,700 jobs during construction and 85 permanent positions once the plant is placed in service.

Virtual image of the Solana solar field

Virtual image of the Solana solar field

Integrated Solar Combined-Cycle (ISCC) Plant

This project includes the design, construction and operation of a 150 MW ISCC plant in Algeria, 20 MW of which will be provided by a solar field of over 180,000 m2 of reflective area.

The plant is in the final construction phase and is expected to be placed in service during 2011.

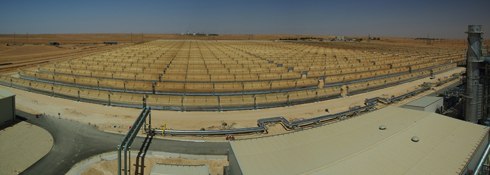

Shams-1

The Shams-1 plant, construction of which began at the end of 2010, covers an area of approximately 300 ha in the Abu Dhabi desert, and will have an installed capacity of 100 MW, by means of 600,000 m2 of parabolic trough collectors.

The project is promoted by a consortium made up of Abengoa Solar, Total and Masdar, which won an international tender to develop and operate the largest solar energy plant in the Middle East. This first solar energy project in the Middle East represents one of the first steps by the Abu Dhabi government to introduce renewable energy into a region which presently remains highly dependent on hydrocarbons, and it marks a strategic milestone for Abengoa Solar due to the immense opportunity for development throughout the Middle East.

Shams-1 incorporates state-of-the-art parabolic trough technology. Among other innovative features, highlights include the plant’s dry-cooling system and its auxiliary heating boiler. The dry-cooling system significantly reduces water consumption at the plant, while the auxiliary boiler, which heats the steam as it enters the turbine, boosts the cycle’s efficiency. These two innovations place Shams-1 at the forefront of parabolic trough technology.

The construction work is progressing according to plan, and the plant is due to be placed in service during the summer of 2012.

Plants in Pre-construction Phase

Abengoa Solar has three plants in possession of all the necessary permits and a defined economic framework, having either been registered in the Spanish pre-allocation registry, or having secured power purchase agreements in the United States.

Extremadura Solar Complex

Two of the four trough plants of the Extremadura complex are in the pre-construction phase. These plants have been included in the Spanish pre-allocation registry and therefore have all the necessary permits for their construction.

When the plants are brought into operation, each will be able to supply approximately 26,000 households while reducing yearly CO2 emissions by 31,000 t.

Mojave Solar

This project stems from an agreement with Pacific Gas & Electric Company (PG&E) to supply the electricity to be generated at the new 280 MW (gross) Mojave Solar power plant. The plant will be located 150 km northeast of Los Angeles, California, and will create 1,600 new jobs in the area during construction and 85 permanent positions for plant operation and maintenance.

In September, Abengoa Solar obtained final licensing approval from the California Energy Commission to commence construction and by the close of 2010 certain construction activities had already got underway at the plant.

It is worth highlighting that this project will provide a major economic boost to the region, and also contribute significantly to California’s renewable energy targets, i.e. replacing fossil fuels with solar energy and other alternative sources to curb greenhouse gas emissions.

Plants under Development

Abengoa Solar has a team of more than 100 employees working on project development in Spain, the United States and the other markets in which it operates. In recent years, Abengoa Solar has channeled considerable time and resources into developing solar power plants. As a result, it has a sizeable portfolio of projects in various development phases in both CSP and PV technologies.

In Spain

Abengoa Solar has more than 1,000 MW in CSP plants prioritized by various regional governments. Most of these plants will be built following the introduction of the new regulatory framework in 2014.

In the United States

Abengoa Solar has a team of experts that has been working on development activities since 2006 and that has enabled the company to launch two major projects in Arizona and California. Abengoa Solar currently has other development projects at various stages in both CSP and PV technology.

International Development

Outside Spain and the United States, Abengoa Solar has development teams able to offer the best possible solution to every need in the markets considered attractive due to their high levels of solar radiation and stable regulatory framework. Abengoa Solar currently has various projects under development in different phases using both CSP and PV technology.

Supply of Key Components

Ensuring a reliable supply of high-quality key components is essential for Abengoa Solar. Consequently, through investee companies, Abengoa Solar controls the design and manufacture of certain components identified as critical.

In the area of power tower technology, Abengoa Solar designs its own heliostat structures. These structures are manufactured by Eucomsa, a subsidiary of Abengoa Solar, and later assembled at each plant’s assembly facility. During 2010, work began to develop new heliostats to further enhance the plants’ technical and economic performance. Furthermore, Abengoa Solar is working with companies specializing in the design and manufacture of receivers in order to maximize performance of these elements while reducing their associated cost.

In the area of parabolic trough technology, Abengoa Solar designs its own collectors. The metallic structures are built by Eucomsa and subsequently assembled at each plant’s assembly facility. Abengoa Solar has introduced a high-performance steel collector at a number of its plants.

ASTRO collector

ASTRO collector

The parabolic trough mirrors are manufactured by Rioglass Solar, with which Abengoa Solar has signed a commercial agreement effectively guaranteeing the supply of this key component. This has translated into lower cost, greater security of supply and improved efficiency and durability of the mirrors in the solar field.

In the area of PV technology, Abengoa Solar has progressed in the development of high-precision trackers for ground-based and rooftop installations as well as in the development of a high-concentration module.

Development of New Technologies

As mentioned above, one of Abengoa Solar’s strategic pillars is the development of new technologies, which enables it to stay ahead of the field in a sector where technologies evolve at a breathtaking pace. This ongoing effort in R&D better enables Abengoa Solar to offer competitive technologies going forward and a portfolio of solutions tailored to each individual project and/or market.

Cameo industrial solar facility integrated into a coal-fired electric power plant owned by Xcel Energy, Colorado

Cameo industrial solar facility integrated into a coal-fired electric power plant owned by Xcel Energy, Colorado

Abengoa Solar’s R&D projects are conducted using the Stage-Gate methodology, based on stage-by-stage development with progress evaluations to gauge the degree of fulfillment of pre-set targets and to assess the potential of the technology under study. This methodology is used to achieve excellence in R&D development and management, while minimizing the risks.

The objectives of the company’s R&D program include the need to obtain better operating temperatures for both power tower and parabolic trough technologies in order to boost the efficiency of the power cycle; enhance plant control and operation systems; cut technology costs; optimize storage systems; and, develop new and more efficient PV technologies.

In line with these challenges, the company continued to operate a number of pilot plants at the Solúcar complex in 2010, which enabled it to consolidate various key innovation concepts:

- Operation since early 2009 of a tower with superheated steam generated in a second receiver reaching temperatures exceeding 500º C.

- Certification of water as an alternative to oil in parabolic trough collector loops. The Direct Steam Generation (DSG) plant, which also came into operation in early 2009, is ratifying the control system developed by Abengoa Solar for direct steam generation.

- Validation of thermal storage technology. The company has been operating a molten salts pilot plant since 2009, and has accumulated considerable experience in the use of this fluid to store thermal energy and to gauge the overall performance of this kind of storage.

- Development of new PV technologies based on the experience and know-how acquired at the PV laboratory, which has been in operation since 2008.

Pilot Molten salts storage plant in operation since 2009 at the Solúcar complex, Seville

Pilot Molten salts storage plant in operation since 2009 at the Solúcar complex, Seville

As a result of this extensive R&D activity, Abengoa Solar has gained proprietary technology protected through patents. Currently, the company holds priority rights over numerous significant and crucial inventions in the solar sector. In 2010 alone, the company applied for 25 patents, while a total of 80 patents have been requested over the last few years.

Abengoa Solar is currently developing both its own research projects and projects in cooperation with institutions and universities. For example, the company enjoys close ties with prestigious institutions such as the National Renewable Energy Laboratory (NREL), the leading renewable energies laboratory in the United States, Spain’s Energy, Environmental and Technological Research Center (CIEMAT), a public research body of excellence in energy and environmental areas, and the thermodynamics department of the German Aerospace Center (DLR).

On a final note, Abengoa Solar is involved in numerous programs promoted by public and private bodies and institutions that offer grants to support R&D projects. In the last three years, the company was awarded five grants for different projects from the US Department of Energy (DOE), a project under the seventh EU framework program, and other projects to develop new technologies subsidized by, among others, Spain’s Center for Industrial Technological Development (CDTI) and the regional government for Andalusia. The CENIT project, led by Abengoa Solar with a budget of €24 M, represents a particularly significant award.

Different concentrating photovoltaic systems

Different concentrating photovoltaic systems