Abengoa

Abengoa

Annual Report 2010

Our Activities

Abeinsa is an international company engaged in industrial engineering and construction. Its business revolves around six divisions or lines of activity: Energy, Installations, Marketing and Ancillary Manufacturing, Telecommunications, Latin America, and New Horizons.

- Energy. Integrated solutions in the energy sector, including the development, funding, engineering, construction and operation of new power plants and industrial facilities, with special emphasis on the solar and biofuel sectors, and streamlining of existing facilities.

- Installations. Engineering, construction and maintenance of electric and mechanical infrastructures and instrumentation for the energy, industry, transportation and services sectors, as well as the installation of insulation and refractory and passive fire protection materials.

- Marketing and Ancillary Manufacturing. Marketing of products associated with the activities described above and the manufacture of auxiliary elements for the energy and telecommunications sectors.

482 MW Ain Beni Mathar ISCC plant in Morocco

482 MW Ain Beni Mathar ISCC plant in Morocco

- Telecommunications. Integration of telecommunication networks and turnkey projects.

- Latin America. A market in which the company has maintained a solid presence for more than forty years through local companies that enjoy full autonomy when carrying out all of the business unit’s activities.

- Abeinsa New Horizons. Engaged in innovative projects relating to sustainable development: hydrogen technologies, energy efficiency, carbon credit management, CO² capture and sequestration and new renewable energies, such as ocean energy.

Energy

This business line focuses primarily on the development, design, construction and maintenance of industrial plants and conventional energy (cogeneration and combined cycle) and renewable energy (bioethanol, biomass, solar, and geothermal) power plants.

When applied to power generation plants, the Operation and Maintenance (O&M) business line carries out preventive, scheduled and corrective maintenance of equipment and systems, and operates them to ensure that the facility operates reliably and is meeting its technical specifications, the ultimate aim being to minimize fuel consumption and greenhouse gas (GHG) emissions while maximizing the load factor (actual vs. projected electricity generation).

Abener

Abener is a market leader in engineering and construction geared towards sustainable development. The key to the company’s ongoing success is innovation, penetration of new emerging markets and its commitment to the environment.

Abener currently operates in three areas of business: solar, biofuels and generation. The company performs turnkey EPC projects using its own engineering capacity and knowledge management processes and also carries out operation and maintenance work (O&M). Abener champions sustainable development and international development through its network of engineering firms and subsidiaries, namely AG Ingeniería (Spain), Abener Poland, Abener North America, Abener India and Abener México.

The company has cemented its position in the Spanish solar energy market with the commissioning of three 50 MW solar thermal power plants at the Solucar platform

(Solnova 1, Solnova 3 and Solnova 4). In tandem with this, construction work is now underway on the solar platforms in Ecija, Extremadura, Cordoba and Ciudad Real, all in Spain. All these facilities comprise two 50 MW plants utilizing parabolic trough technology, with the exception of the Extremadura facility, which features four 50 MW plants.

A major milestone on the international stage was the company’s completion of the world’s largest ISCC plant in Morocco (482 MW). Abener also expects to start up a further ISCC plant in the first half of 2011. These two ambitious projects have afforded Abener a position of technological leadership worldwide and underscore the company’s unflinching commitment to society and the environment.

In the solar energy division, Abener secured contracts to construct what will be two of the world’s largest solar thermal power plants, namely Shams-1 (100 MW) and Solana (280 MW gross), located in the United Arab Emirates and North America, respectively, and both currently under construction. The Shams-1 project was awarded under an EPC agreement through an international tender process staged by Masdar. The developer is the company Shams One Company, comprising Masdar, Total and Abengoa Solar. Thanks to just shy of 600,000 m2 of parabolic troughs, the plant will generate enough electricity to supply 62,000 households.

The Solana project, the world’s largest solar power plant with 280 MW of gross power, utilizes parabolic trough technology with thermal storage achieved through molten salts to extend the hours over which the plant can operate during the day and at night. The contract also envisages full EPC.

Biomass cogeneration plant in Brazil

Biomass cogeneration plant in Brazil

Abener has strengthened its leadership in engineering and constructing bioethanol plants by completing work on one of the world’s largest bioethanol plants in Rotterdam (the Netherlands), and two other large plants in the United States (Indiana and Illinois). As a further illustration of its commitment to innovation, Abener is currently collaborating with the client to develop second-generation bioethanol plant technology for the Hugoton plant in Kansas (USA), which will run on cereal straw instead of grain.

Abener has also enjoyed considerable success in the conventional electrical power generation market, ranging from upgrade work and simple/combined cycles to motor and cogeneration plants. The operational success of these industrial facilities is a fine illustration of Abener’s formidable capacity in this area. Prime examples include the construction work currently underway on the new 300 MW cogeneration plant for Pemex, and the two 70 MW biomass cogeneration plants (bagasse and sugarcane) in Brazil, which were completed in 2010.

Operation and Maintenance

The O&M division worked on five different plants in 2010: Four cogeneration facilities sited in Alcantarilla (Murcia), Motril (Granada), Ayamonte (Huelva) and Cuevas de Almanzora (Almeria), all in Spain, and the Ain Beni Mathar ISCC plant in Morocco. The total power output of all these facilities combined amounts to 579 MWe.

2010 also saw the O&M division select the staff who are to form part of the O&M team for the 150 MW ISCC plant in Hassi R’Mel (Algeria). This new workforce is actively involved in the start-up of the plant and is applying the wealth of experience built up by Abengoa in handling O&M work on North African plants. This know-how will be enormously useful for further developing solar power production facilities within this market, one of the strategic horizons offering the most promising opportunities for the company in terms of business operations.

In 2010, the company successfully implemented a new maintenance management system at the Ain Beni Mathar ISCC plant in Morocco, which will afford it greater management control and efficiency at the plant. The next plant to feature this same system will be the 150 MW Hassi R’Mel plant in Algeria.

Installations

As part of Abengoa’s strategy of specializing in key areas, 1994 saw the company incorporate Instalaciones Inabensa SA, the parent company of this particular line of business, which encompasses all activities associated with electrical and mechanical installation work, instrumentation, large power lines, railroad business, maintenance, manufacture of electrical panels and cabinets and telecommunications, all of which have been core activities at Abengoa since its inception back in 1941.

Abengoa Bioenergy Netherlands bioethanol plant in the port of Rotterdam, the Netherlands

Abengoa Bioenergy Netherlands bioethanol plant in the port of Rotterdam, the Netherlands

Inabensa

Inabensa operates in the industrial and infrastructure engineering, construction and maintenance market within the energy, industry and, transportation, services and communications sectors. It provides global solutions to meet the most stringent demands of its customers, who continue to place their trust in Inabensa due to the sheer quality of the services it offers.

Year after year, burgeoning business overseas has enabled the company to strengthen its position in its strategic markets through its subsidiaries and permanent establishments in Portugal, France, Morocco, Australia, India, Costa Rica, Abu Dhabi, Libya, China and Saudi Arabia.

It currently operates in the following areas.

Electrical Installations

Inabensa’s work in this field encompasses the engineering, construction and outfitting of infrastructures.

The following milestones were of particular note in 2010:

- In the industrial sector, Inabensa completed electrical upgrade work on the Ford factory in Almusafes for the Fiesta and C-Max project, and also completed the new power station for Alicante airport, with its network of distribution galleries for electrical services, both projects in Spain.

- The company completed work on remodeling the stations on line 5 of the Madrid Subway, lighting the tunnel on line 6, and upgrading the Moncloa, Manuel Becerra, Diego de León and Ciudad Universitaria stations for Metro de Madrid.

- Inabensa awarded a contract to remodel the existing power lines in northern Catalonia in order to increase their transmission capacity. For Adif, the Spanish railway infrastructure administrator, Inabensa continued work on the services affected by the high-speed Madrid-Barcelona-French Border railway line, specifically the following sub-sections: La Torrassa-Sants, Hospitalet-La Torrassa and Sants-Sagrera.

Electrical switchboard manufactured by Inabensa

Electrical switchboard manufactured by Inabensa

Mechanical Installations

In this particular field, Inabensa is involved in the design, supply, manufacture, assembly and testing of mechanical systems for large projects.

At present, the mechanical assembly department is collaborating with other parties to construct the Ecija 1 and 2 solar power plants, and to manufacture, supply and assemble the piping and equipment for the entire Heat Thermal Fluid (HTF) system and power island.

Maintenance and Instrumentation

In the field of maintenance and instrumentation, Inabensa engineers, supplies, assembles, calibrates and implements process control installations, while also providing a fully-comprehensive installation and infrastructure maintenance service. Highlights in this respect include the work performed on the fuel storage facilities for CLH in Barcelona, Alcazar de San Juan, Albuixech and Torrejon, all in Spain.

Rail

Inabensa’s projects on conventional rail, high-speed rail, city rail and light rail systems include the design, construction and start-up of all electric drive systems.

Highlights for 2010 include the start of a contract awarded by Adif to construct the overhead contact line and associated systems for the new high-speed Madrid-Eastern Coast railroad access route along the Motilla del Palancar-Valencia and Motilla del Palancar-Albacete sections. In addition to this high-speed project, Inabensa was also involved in conventional railway work for Adif as work got underway to construct the overhead contact system for the Albacete-Almansa and Variante de Mojon Blanco sections on the Madrid-Alicante line, and the company also completed upgrade work on the catenary system along the Gallur-Castellon and Mataporquera-Reinosa sections.

Barcelona subway station

Barcelona subway station

Large Lines

In the large power line business, Inabensa engineers, constructs and commissions high and medium voltage power systems.

It has worked extensively with the Spanish power transmission corporation Red Eléctrica de España (REE), and has similarly taken part in numerous projects to construct new 400 kV power lines, including in particular: termination of the Arcos-La Roda, Aparecida-Tordesillas line; the Torrente electrical substation; the Udalla electrical substation; and a new section on the Soto-Penagos line in Asturias.

Manufacturing

The company’s production workshops in Seville and Alcala de Henares (Spain) and in Tianjin (China) design, manufacture and test all electrical and electronic products.

Highlights include production of rail control cabinets and ticket vending and traffic control machines for Jaen light rail system. The facilities also manufacture equipment and associated electronics to implement contactless smart technology for the transportation sector within the context of the Barik project.

Insulation, Refractory and Passive Fire Protection

In this particular field, Inabensa designs, constructs and carries out maintenance work on installations, while also manufacturing its own range of products and insulation material.

The year 2010 witnessed successful completion of the insulation work on the Solnova 3 and Solnova 4 plants at the Solucar solar platform. Furthermore, the Sulphur Block plant was completed under the ACPDM project, and extensions were made to the Cepsa refinery in Huelva. Contracts were also awarded for work on the Helios I and Helios II solar power plants in Ecija (Spain).

The company Técnicas Reunidas entrusted Inabensa with the task of fireproofing and supplying the necessary material for the Galp plant in Sines (Portugal), and the company has also been kept busy supplying material to different fireproofing solution providers in the construction and industrial sectors.

Service Concessions

The concessions division caters to the needs of modern society and is witnessing an increasing demand from various sectors for companies capable of providing operation and maintenance services and services to enhance infrastructures and public services.

For example, the parking lot at the Hospital Costa del Sol was brought into service in 2010 to coincide with completion of the hospital, thus complementing the other concessions currently in operation, such as the Hospital de Aranjuez and the court buildings in Olot, Cerdañola and Santa Coloma, all in Spain.

The photovoltaics department was also involved in projects for roof-mounted solar facilities, including extension work on the World Expo Zaragoza site, the solar power plant at the municipal swimming pool in San Roque (Cadiz) and the desalination plant in Almanzora (Almeria), all in Spain.

Overseas

In India, construction work continued on two 400 km sections of the 765 kV Biswanath Chariyali-Agra direct current power transmission line, and work was completed on the awarded section of the 400 kV Bariapada-Bhaddrak line.

In Saudi Arabia, construction got underway on the high voltage 132 kV power line in Qurayyat for the SEC (Saudi Electricity Company). The company is also constructing the Jeddah and Riyadh GIS (Gas Insulated Substations), both 380 MW and 132/13.8 kV, again for the SEC.

The manufacturing segment also fared well thanks to the company’s subsidiary in China, which was involved in projects for various different clients and countries.

Telecommunications

The telecommunications division constructs and maintains outside plant, supplies customer loops and equipment and integrates products and services in order to deploy, install and operate telecommunication networks. This is carried out by both Abentel and Inabensa’s own communications divisions.

Abentel

During the year, the company continued to work on the 2007-2012 Global Customer Loop Agreement with Telefónica de España SAU, with implementation ongoing in the provinces of Alicante, Badajoz, Barcelona (where Abentel’s initial stake of 7 % of the province has been extended to 10 %), Cadiz, Jaen, Madrid, Seville, Tenerife and Valencia. Abentel is Telefónica’s chief collaborator on this particular agreement in Spain.

Abentel fleet in Spain

Abentel fleet in Spain

Over the year, 256,000 new customer subscriptions were secured for Telefónica (132,000 for voice, 110,000 for ADSL and 13,000 for Imagenio) and nearly 500,000 faults were repaired.

As part of the activities envisaged in the agreement, Abentel has been involved in the project awarded to Telefónica by the Spanish government to roll out the Iris Nova Network throughout Spain, with the scope of the network mirroring the territorial scope of the agreement. To date, a fiber optic network has been laid to link different universities and state-owned research centers, with a grand total of 1,000 km of cable containing 64 optical fibers laid in eight of the nine provinces awarded under the agreement.

Abentel is also taking part in a project to transform Telefónica’s access network. The initiative entails the gradual implementation of FTTH (Fiber To The Home) networks throughout various Spanish cities. The work essentially involves preparing the trunk infrastructure and the end-user access infrastructure through fiber optic cables in order to provide Telefónica customers with the considerable bandwidths that these networks have to offer. The infrastructure deployed to date extends to 32,500 households, which are supplied through 143 km of fiber optic cable (between 64 and 256 optical fibers) for the trunk network, and nearly 200 km of 32-fiber or less cable for the end-user access network.

Inabensa Communications Division

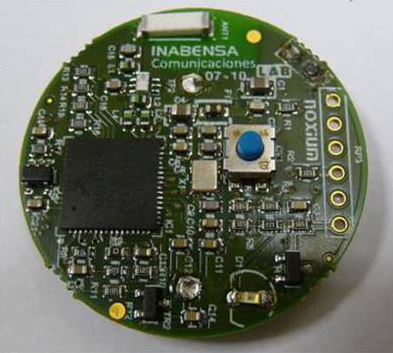

Inabensa’s communications projects embrace the design, supply, manufacture, assembly and testing of telecommunication systems and equipment.

Highlights for 2010 included ongoing projects with technological partners, such as Huawei and Ericsson. Thanks to Inabensa’s work with Huawei, the company was named Outstanding Technologies Partner in recognition of its development, capacity and technological cooperation. It was also presented with the European Partner Award, cementing Inabensa’s position as one of Huawei’s most trusted collaborators in Europe. Inabensa is also continuing to collaborate with Ericsson at switching exchanges for Orange, and is similarly working with NSN on projects for the operators Orange and Telefónica, consisting of DNO maintenance and UMTS installation work.

Telecommunications system designed and manufactured by Inabensa

Marketing and Ancillary Manufacturing

Within this field, Abeinsa primarily manufactures and markets products related to the business unit’s activities, while also producing auxiliary elements for energy and telecommunications.

Nicsa held on to its dominant position in the Spanish market and consolidated its international status as a supplier of electric materials, instrumentation and communications for the chemical and petrochemical industries, refineries, combined cycle, solar thermal, nuclear and thermal power plants and heavy industry in general. In 2010, the company successfully tackled a number of major projects and its subsidiaries in Mexico and North America reported very healthy results.

Abencor continues to focus its business model on the markets typically associated with sustainable development. The company was primarily engaged in creating three new areas in 2010, specifically two sales divisions (one dedicated to Spain and the other to overseas markets) and a procurement division. The Spain division is focusing on existing customers, catering to their needs and forging as close a relationship as possible, while the exports division is mainly targeting business in Latin America (Brazil, Chile, Peru and Mexico), Europe (Portugal and Germany) and the Far East (especially India). The procurement division is geared more towards relations with the company’s key suppliers, while also formulating offers and seeking out and endorsing attractive new products.

In 2010, Eucomsa further cemented its standing as a prime supplier of solar structures, accounting for over 70 % of the company’s total performance. It also regularly improves upon the design of parabolic troughs, thus making them more competitive within the market and affording Abengoa significant cost savings. Along with the solar energy business, highlights for 2010 include projects carried out for REE as part of the company’s core tower manufacturing business.

Driven forward by the wealth of experience and know-how it has built up in exports, Comemsa remains very active in the Latin and North American markets, where it created the company Power Structures in 2009 to sell its products and provide customer service.

Comemsa is engaged in the manufacture of metallic lattice towers for power lines, structures for electrical substations and telecommunications towers. In 2010, it increased its floor and storage area to meet heavy demand and ensure full customer satisfaction.

Nicsa

Highlight projects for 2010 include the following:

- Project to extend the Repsol refinery in Cartagena, Murcia (Project C10): Supply of power cables and instrumentation, lighting, trays, conduit, junction boxes, compression glands, control stations, power outlets, panels, capacitor batteries and direct current supply boxes.

- Fuel Oil Reduction Unit project for Petronor, Repsol’s refinery in Bilbao. Fully-comprehensive agreement to supply all the electrical equipment and instrumentation assembly work for the project. The scope includes: electrical and instrumentation cables, grounding, trays, conduits, lighting, junction boxes, compression glands, switching stations and power outlets.

Repsol refinery where Nicsa is supplying material and equipment

Repsol refinery where Nicsa is supplying material and equipment

- Reconversion of Galp Energia’s refinery in Sines (Portugal), along with various combined cycle facilities, all contracted through the company Técnicas Reunidas.

- Platforms for Pemex, specifically the residential Litoral Tabasco platform and the PG-Zaap-C electrical power generation platform, both secured through Dragados Offshore, including the supply of cables, connectors, lifting equipment, winches, telecommunications system (turnkey), UPS, CSM and bushings.

Supply of cables for the Norte Brasil project

Supply of cables for the Norte Brasil project

Abencor

Highlight projects for Abencor over 2010 include:

- Supply and assembly for the EDP Group of two power transformers for the Pestera substation, and a further two for the Cernavoda substation, both in Romania. Supply of power transformers for the Helioenergy and Solacor solar thermal plants.

- Milestone projects outside Spain were as follows: in Brazil, the supply of AAAC 1055 MCM conductor cable (61 alloy/3.34 mm) in the Amazon Rainforest (Manaus, Urucara and Itacoatiara) for the company Manaus Transmissora de Energia SA; in Chile and Portugal, ACSR Canna conductor cable was supplied in Antofagasta for Abengoa Chile and in Angola for Eurico Ferreira SA; in Mexico, 205 MVA principal transformers were supplied to the joint venture Abener Inabensa NP Tabasco I for the Nuevo Pemex cogeneration project in Tabasco; in Portugal, solar panels; in Algeria, measurement transformers for Electricidad Industrial Portuguesa; and in Germany, solar panels for Soellinguer and Solarsysteme Bayer.

Tower designed and constructed by Comemsa

Tower designed and constructed by Comemsa

Eucomsa

Highlight projects for this company include the following:

- Supplies for the Ecija 1, Ecija 2, Cordoba 1, Shams 1, Cordoba 2, Helios I and Solaben 3 solar power plants.

- Major power transmission line contracts included the Abanto-Penagos-Güenes, L/400 kV Brazatortas-Manzanares, L/400 kV Fuendetodos-Mezquita, Olmedilla-Moncada and the 400 kV Almaraz-San Servan lines for REE in Spain, along with various power lines in Northern Ireland and sundry supplies for various customers (Energy Ventures, etc.).

- Highlights in the mobile telephony segment were the towers constructed for Inabensa Maroc in Morocco and the towers for various Spanish projects of Inabensa (Telefónica, Vodafone, Adif, Aena, etc.).

- As regards testing stations, highlights included Balfour Beaty (400 kV), Inabensa (Costa Rica power towers), Ireland’s ESB, and sundry towers for customers such as Eléctrica de Medellin (Siepac), Made, Jovir, Andel, and so on. Testing station equipment was also provided in order to make improvements to the new parabolic trough design. This line of business reported year-on-year growth.

The metal sheet and plate division was disbanded in 2010 and merged into the structures division, although its main product remained untouched - fiber optic cabinets for Telefónica. Part of the division’s floor area was also used for welding work in 2010, the aim being to increase this activity through the introduction of new robots in 2011.

Comemsa

The company continued to supply structures for solar power plants in 2010, on this particular occasion for the Shams-1 project in the United Arab Emirates. In the towers division, towers were successfully supplied for the 500 kV Comahue-Cuyo power transmission line, along with structures for the Nea-Noa substation, both for Teyma in Argentina. In Mexico, Comemsa supplied the power evacuation line for the cogeneration plant that Abengoa México and Abener are constructing for Pemex.

Further highlights included the supply contracts secured in the United States: Southern California Edison awarded the company segments 6, 7 and 8 under the TRTP project for a grand total of 16,500 t, while the company PSEG in New Jersey awarded segments 2, 2A and 3, totaling more than 10,000 t of supplies.

Latin America

The Latin America business unit has created local companies to operate in the following countries: Argentina, Brazil, Chile, Mexico, Peru and Uruguay. It operates as an independent group within Abeinsa, in that it works within a specific market where the company has enjoyed a solid presence for over forty years and where the different group companies conduct all of Abeinsa’s lines of business, including energy, installations, telecommunications, marketing and ancillary manufacturing, civil engineering and environmental services.

Teyma Abengoa

Abeinsa’s local company in Argentina remains a key player under the federal 500 kV and 132 kV power transmission line project.

Teyma Abengoa has also made several successful ventures into hydraulic piping and water treatment in an attempt to diversify its range of local products and services, and was similarly involved in expanding the wastewater network for the municipality of San Vicente.

2010 proved to be a key period for the company in terms of sales. Despite having the same corporate structure as in 2009, Teyma Abengoa managed to double the volume of bids presented to various public and private clients. Although some of the bids have yet to be awarded, the company remains upbeat about its chances, and during 2010 it managed to secure a core engineering contract from a private mining client, Vale Do Rio Doce, under which the company is to provide electrical power to the Potasio Rio Colorado mine in Malargue, Mendoza.

The main contracts performed in 2010 include:

- 500 kV Comahue-Cuyo (southern section) interconnection project to connect the Agua de Cajon substation in the province of Neuquen with the Gran Mendoza substation located roughly 707 km away in the province of Mendoza. This will require a 500/220 kV substation called Los Reyunos (currently Rio Diamante) midway between the two points.

- 500 kV high voltage power line spanning 518.6 km between the Agua del Cajon and Los Reyunos substations.

- Expansion and upgrade of the Agua del Cajon transformer station in Comahue, Neuquen province. The existing facilities will be expanded to feature a breaker and a half scheme.

Teyma Abengoa assembling transmission towers

Teyma Abengoa assembling transmission towers

Abengoa Brasil

Impressive project intake in 2009, coupled with numerous concessions in commercial operation, saw the company experience dizzying growth in 2010.

Having already successfully developed the core aspects of its strategic plan, while at the same time forging strategic alliances, insourcing knowledge and diversifying business, Abengoa Brasil was able to acquire a 50.1 % stake in Damp Electric, a manufacturer of metallic structures, and also incorporate, along with Teyma, the company Abratey, which will carry out civil engineering work in the country. The company continued to diversify its range of products and services over the year by venturing into wind power and water management.

Power Transmission Grid Concessions Division

In Brazil, the company is currently operating 2,877 km of high voltage lines (230-500 kV) and boasts a further 4,064 km of lines through new concessions currently undergoing engineering and/or construction work.

The company remains one of the country’s leading private power transmission companies, and was involved in the following key projects in 2010:

- ATE IV Curitiba-Bateias line, ATE V Jaguariaiva-Itarare line and ATE VI Campos Novos-Videira, all of them brought into service in the south of the country.

- Installation permit obtained for the Orximina-Silves-Lechuga under Manaus power transmission line, and the corresponding construction work got underway.

Engineering and Construction Division

The company has signed a commitment to forging strategic alliances in order to drive forward growth, as evidenced by its acquisition of a 50.1 % stake in Damp Electric, a supplier of key products in the engineering and construction value chain, such as the metallic structures needed to construct transmission towers.

Abengoa Brasil employees carrying out O&M work on a power transmission line

Abengoa Brasil employees carrying out O&M work on a power transmission line

With a view to securing a better foothold in the hugely important civil construction market in Brazil, Abengoa Brasil and Teyma incorporated the company Abratey in 2010, which will harness the capacities of both its founding companies to capture business opportunities in the Brazilian civil construction and engineering market.

The company has reached the decision to use its own resources when engaging in construction work, given the strategic importance of cutting costs and in light of the financial crisis currently plaguing the companies that Abengoa Brasil used to subcontract to construct its installations. The engineering department was also consolidated over the year and now provides its services directly to assist the company with its projects.

The company remains one of Brazil’s leading private power line construction firms, with key projects for 2010 including:

- Start of engineering on the 600 kV direct current Porto Velho-Araraquara power line. This is a truly groundbreaking milestone in that it is one of the world’s longest direct current lines at 2,350 km.

- Construction work completed on the lines and substations needed to connect the São João and São Luiz power stations to the electricity grid in the state of São Paulo.

- Completion of construction work and start-up of the 132 km ATE V power line.

- Project initiated to increase transformation power at the ATE VII Foz de Iguaçu and ATE III Itacaiúnas substations.

- Work continued on the turnkey EPC agreement signed with Electronorte to construct the Ribeiro Gonçalves-Balsas transmission line.

- Start of construction on the 500 kV Oriximina-Silves-Lechuga power line under the Manaus project after obtaining the installation permit in November.

- The company’s own engineering department started engineering work on the 230 kV Jauru-Porto Velho power line as part of the Pre-Madeira project.

Bargoa

Bargoa specializes in engineering product development, the manufacture of thermoplastic injection molds, stamping of metallic components and final product assembly. The company mainly operates within the telecommunications sector.

Expert staff use cutting-edge equipment at the company’s laboratories to carry out the necessary trials and testing to verify that the manufactured products and components are up to standard. This work is carried out at the Camarín and Lagoas plants in the state of Rio de Janeiro, Brazil.

The company comfortably met all the objectives it had set itself for 2010 by increasing its share in the Brazilian market and launching new products. It was also spurred on by renewed investment in the sector over the second half of the year. Key accounts include the operators Oi, Telesp, Brasil Telecom, Eltek and Embratel. Outside Brazil, the operators Telefónica de Chile, Telefónica de Argentina, Japan’s Nobargo and Korea’s A.J. World are key clients.

Abengoa Chile

The year 2010 started out with a national catastrophe that hit the economy hard for the first few months. The earthquake and resulting tsunami had a heavy bearing on the country’s investment priorities and certain important projects from the private sector were put on ice. On top of this, the country saw a change of government in 2010, with the market on tenterhooks as to how its economic policy would pan out. Yet despite these setbacks, Abengoa Chile held on to its market share.

Overhead line constructed by Abengoa Chile in the commune of Sierra Gorda

Overhead line constructed by Abengoa Chile in the commune of Sierra Gorda

Of note among the main projects secured and performed in 2010 were the following:

- Construction completed on two overhead lines for Minera Esperanza. The first was 110 kV and 55 km in length, spanning the Chacaya substation and the Principal Puerto substation in Michilla. The second, was 2x220 kV, 82 km in length, spanning the El Cobre and Esperanza substations, is used to deliver electricity to the Esperanza Project, located in the commune of Sierra Gorda, 150 km from Antofagasta.

- Ongoing construction for Pacific Hydro Chile of the interconnection substation and modification of the Maitenes and Sauzal substations and the 2x220 kV power transmission line between the Chacayes and the interconnection substations. The work requires the company to configure the interconnection substation as a SF6 gas insulated substation (GIS), modify and extend the Maitenes and Sauzal substations and construct a 2x220 kV line between Chacayes and interconnection.

- In 2010, the client Aguas Andinas awarded Abengoa Chile a contract to renovate and install drinking water pipelines. The company was also involved in the Gran Alimentadora Valparaíso pipe relaying project along the 2,850-5,528 km section.

Abengoa México

Abengoa México successfully overcame the economic crisis in 2010 by seizing a number of important opportunities for sustainable growth. Its strategy is currently geared towards greater involvement in projects from Pemex and other private clients. It operates while keeping energy consumption and GHG emissions to a bare minimum, thus helping to champion sustainable development.

- Electric division: despite the major slump in project intake within the electric sector, Abengoa México remains very much a market leader in the Mexican electrics market, and was awarded a contract under the 248 SLT 1401 project to construct five substations and four power transmission lines for the Mexican Federal Electricity Board (“Comisión Federal de Electricidad”).

The company is also participating in the construction of the substations and transmission lines for the cogeneration plant that the temporary joint venture Abener-Inabensa is currently constructing for Pemex in the south-east of the country. - Oil and gas division: Abengoa México is in the process of consolidating its position in this particular market, and is now working simultaneously at Pemex Refinación, Pemex Gas y Petroquímica Básica and Pemex Exploración y Producción.

- New business development division: the division secured and performed numerous projects in 2010, including installation of the 130 kW COP16 photovoltaic system for Enel Green Power in Cancun, and the turnkey project for the La Mata substation (230-115 kV) and medium voltage network for the La Mata La Ventosa wind farm.

- Concessions of iconic buildings: construction work got underway on the Centro Cultural Mexiquense de Oriente cultural center in Texcoco, State of Mexico.

Mesteñas substation in the state of Chihuahua, Mexico

Mesteñas substation in the state of Chihuahua, Mexico

Progress was made in 2010 towards meeting the objectives set for Abengoa T&D, Abengoa México’s subsidiary company in the United States. Strategic ties were forged with local companies interested in supporting the company as it performs its projects. Moreover, business opportunities were pinpointed and closely monitored both for EPC projects and concessions of power transmission lines.

Abengoa Perú

2010 proved to be another excellent year for Abengoa Perú, which reported a year-on-year jump in business turnover and cemented its position as a key player in the power transmission, water and treatment sectors.

The main projects completed or in progress include:

- Sociedad Minera Cerro: Batch 1 and 2 Arequipa, extension and enhancement work on the metropolitan drinking water system for Arequipa, Peru’s second most populated city behind Lima.

- Construction of the Baños V hydro power station in the province of Huaraz for Empresa Administradora Chungar SAC.

- Construction of the high voltage 220 kV Carhuamayo-Carhuaquero line and associated substations. The project envisages the design, supply and construction of the entire electricity system, and operation and maintenance for a 30-year term.

- Construction of the 500 kV Chilca-Marcona-Ocoña-Montalvo power transmission line and associated substations, including the installation of two series compensation capacitors at the Ocoña substation.

- Construction of the 220 kV Paragsha-Francoise & Amp. SE Paragsha II and Nueva SE Francoise power transmission line, including operation and maintenance for a 30-year term.

Peasants next to the Cajamarca substation on the 220 kV Carhuamayo-Carhuaquero transmission line in Peru

Peasants next to the Cajamarca substation on the 220 kV Carhuamayo-Carhuaquero transmission line in Peru

Teyma

Teyma experienced impressive growth in 2010 both in Uruguay and overseas, with the year witnessing not only the commencement of operations in the Middle East, North America and Brazil, but also sharp growth in Spain.

Teyma Construcción

Highlight projects completed or in progress in 2010 are as follows:

- 500 kV stations for the Administración Nacional de Usinas y Transmissiones Eléctricas. The project, currently in progress, encompasses the supply and turnkey installation of two.

- 500 kV stations, which will effectively connect the Punta del Tigre power line with the existing Uruguayan 500 kV electricity grid.

- Extension of the Sanatorio Americano health center, entailing the construction of a new. 8,000 m² building to be annexed to the existing structure.

- Structural and hydraulic rehabilitation work for Montevideo City Hall in relation to the sewage and drainage system for the Piedras Blancas-Hipódromo neighborhood and Hipódromo industrial estate.

- Completion of basic work on the Sixth Pumping Line (“Sexta Línea de Bombeo”) for the Administración de Obras Sanitarias del Estado (OSE), the aim being to resolve the drinking water supply problems being experienced in the western parts of the departments of Montevideo and Canelon

Teyma Forestal

This company provides a wide range of services to the Uruguayan forestry sector, focusing primarily on the harvesting, extraction and transportation of wood, whether as a raw material for industrial processes or as an energy source. The company remains actively involved in numerous mechanized harvesting agreements to produce cellulose pulp for Forestal Oriental SA and Sierras Calmas SA (ENCE), and is also supplying forest biomass as an industrial energy source.

Teyma Medioambiente

Urban waste management company that provides groundbreaking technical solutions. Operating under the name Consorcio Ambiental del Plata (CAP), it provides street waste container collection and sweeping, washing and cleaning services in a specific area within Montevideo city center.

Teyma Internacional

Specializing in turnkey renewable energy projects, Teyma Internacional is currently acting as an executor of Abengoa’s investments in new biofuel and solar power plants, effectively channeling the projects undertaken in Europe, Africa and the United States.

The company is still busily involved in the engineering management and consultancy project to construct a hybrid 150 MW solar-gas power plant utilizing parabolic trough technology in Hassi R’Mel (Algeria), and EPC construction was also completed in 2010 on two cogeneration plants for Abengoa Bioenergía in São Luiz and São Joao (Brazil).

Hybrid solar power plant in Hassi R’Mel, Algeria

Hybrid solar power plant in Hassi R’Mel, Algeria

Teyma España

In 2010, Teyma Gestión de Contratos de Construcción e Ingeniería managed to double its turnover for 2009.

High levels of customer and employee satisfaction paved the way for the company to deploy workers in Algeria to wrap up the project underway in the country and in Abu Dhabi to start work on the Shams-I plant. It also successfully implemented Teyma in the United States and provided invaluable assistance in constructing the eight solar thermal power plants in Spain.

Teyma USA

The year 2010 saw Teyma USA consolidate its position in North America following its incorporation in July of 2009. Its permanent offices in Phoenix, Saint Louis and Los Angeles receive and process orders for engineering, planning and permitting work from Abengoa Solar and Abengoa Bioenergy.

A collaboration agreement between Abener North America and Teyma USA was signed to construct Solana, the world’s largest solar power plant located in Phoenix, Arizona.

In 2010, the company acquired Abacus Project Management, a North American market leader in the project construction and management sector.

Abeinsa New Horizons

This line of business provides solutions geared towards sustainable development: hydrogen technologies, energy efficiency, carbon credit management, CO2 capture and valorization and new renewable energies.

Hynergreen

Hynergreen Technologies SA, Abengoa’s subsidiary specializing in hydrogen technologies and fuel cells, continued to report growth both in terms of order intake and performance, and also the volume of R&D staff and investment in new technologies, with growth standing at 42 % and 20 % respectively. The company is currently acting as president of the Spanish Technological Platform for Hydrogen Technologies and Fuel Cells (“Plataforma Tecnológica Española del Hidrógeno y de las Pilas de Combustible”, or PTE-HPC).

Highlight projects for the year include:

- Ongoing engineering and supply work for Navantia within the context of the air-independent propulsion (AIP) system for the new S-80 submarines.

- Construction of the prototype bioethanol processing system for the power adjustment and control systems of the AIP system.

- Start-up of the Hércules Project service station, southern Spain’s first hydrogen fuel service station. In tandem with this, the company was involved in launching an electric car fitted with polymer fuel cells.

Hydrogen generation system and fuel cell for the Palmas Altas Campus

Hydrogen generation system and fuel cell for the Palmas Altas Campus

In the field of internal R&D, Hynergreen has continued to implement its strategic plan by carrying out projects and activities in two core areas:

- The production of hydrogen from renewable sources (solar, wind, biomass and biofuel), including storage and transportation.

- Electric power generation through fuel cells, embracing the entire process and including such aspects as power adjustment, control, security and user interface. Milestones in this particular area include: energy storage system for the Palmas Altas campus; studies into the use of fuel cell systems for railroad applications; and the development of new mobile systems for generating electricity from fuel cells.

Zeroemissions Technologies

The company offers solutions to climate change by promoting, developing and trading carbon credits and relying on the company’s corporate carbon strategy, voluntary emissions compensation and innovation in GHG reduction technologies.

Highlight projects for this division include:

- Heightened demand for strategic consultancy services. The United Nations awarded Zeroemissions a contract to address the national bioenergy strategy for Lebanon and to develop a financial means of improving access to borrowing for the industries taking part in an energy efficiency project in El Salvador.

- Nuevas Tecnologías, the division specializing in R&D&I projects aimed at honing technologies and knowledge that will help to curb GHG emissions, including the sale of CO2 neutralization certificates from the eBay website.

Emissions neutralization certificate available from eBay

Emissions neutralization certificate available from eBay

- Projects for 2010 focused on the need to monitor, reduce and harness the methane generated from the decomposition of organic waste, including studies into cooling systems that employ gases less harmful to global warming.

With regard to labeling and certification, and in addition to broadening its business in emissions inventories, Zeroemissions expanded its existing products and services further by incorporating an enhanced range of value-added services, such as analyses of product life cycles and calculations of carbon footprints, including the possibility of official certification in accordance with existing standards. The company also launched the on-line Campus Zero training platform, intended for professionals interested in learning more about the sector.

Inabensa I+D

Inabensa is a company with an impressive and long-standing track record in the field of technological research and development. It is actively involved in the numerous initiatives promulgated by national and international governments with universities and research centers. These include the development of projects relating to energy efficiency, renewable energies, ocean energy, geothermal energy, CO2 capture and sequestration technologies, and telecommunications.