Abengoa

Abengoa

Annual Report 2011

- Activities

- Activities

- Concession-type Infrastructures

- Our Activities

Transmission lines

Abengoa currently has 9,002 km of transmission lines under concession in Brazil, Chile and Peru, with an average remaining life of 23 years, specifically:

- Brazil: 6,696 km of lines under concession.

- Peru: 2,001 km of lines under concession.

- Chile: 305 km of lines under concession.

The company also expects to commission the following lines in the coming years:

- In 2012: Brazil - Manaus and Línea Verde lines, spanning a total of 586 and 987 km, respectively.

- In 2013: Brazil - North Brazil line. This line is set to become the world’s longest DC (direct current) transmission line at 2,375 km. Plus the ATS line in Peru, measuring 872 km.

Detailed below are Abengoa’s main concessions by region:

Brazil

Abengoa remains a prominent player in the Brazilian power transmission market. It currently possesses over 6,000 km of transmission lines under concession from public bodies (accounting for roughly 8 % of the national basic power grid).

The following projects are currently in operation:

- STE - Sur Transmisora de Energía. Transmission line spanning 386 km awarded by Aneel.

- 500 kV Uruguaiana-Maçambará section.

- 230 kV Maçambará-Santo Ângelo section.

- 230 kV Santo Ângelo-Santa Rosa section.

STE controls the line, which has been in operation since 2004 and traverses 13 municipalities within the state of Río Grando do Sul.

- ATE Transmisora de Energía. 525 kV Londrina (SC)-Assis (SP)-Araraquara (SP) power line, covering a total distance of 370 km.

The transmission line (TL) comprises the 525 kV Londrina-Assis section between the Londrina substation, located in the municipality of Londrina (state of Pará), and the Assis substation, located in the municipality of Assis (state of São Paulo), measuring approximately 120 km; and also the 525 kV Assis – Araraquara TL between the Assis substation and the Araraquara substation, located in the municipality of Araraquara (also in the state of São Paulo), measuring roughly 250 km.

The underlying reasons for the project, which will be carried out by upgrading existing power transmission systems in the southern and southeastern regions, are as follows:

-

To enable surplus power to be transferred between the southern and southeastern regions, particularly within the metropolitan area of São Paulo and the region of Londrina.

-

To upgrade existing infrastructure within the southern/southeastern regions to enable them to receive up to 3,000 MW of electrical power.

-

To upgrade power exchange capacity to 2,500 MW between the north-northeast and south-southeast-central-west systems.

-

To interconnect the various hydrographic basins in Brazil.

-

To help increase the reliability, security and stability of the Brazilian electrical system.

-

To bring about an effective average increase of 900 MW in the guaranteed power provided by the Brazilian electrical system.

- ATE II Transmisora de Energía. Colinas-Ribeiro Gonçalves-São João do Piauí-Sobradinho TL, covering a total distance of 937 km.

This TL was awarded as a public concession for the operation and exploitation of electrical power and includes the construction of basic grid transmission installations within the electrical system for Aneel. The line consists of 500 kV installations between Colinas and Sobradinho, starting from the Colinas substation in Tocantins state and extending to the Ribeiro Gonçalves substation in Piauí state, spanning a total of 374 km; a second section measuring 353 km and linking the Ribeiro Gonçalves substation to the São João do Piauí substation, also in Piauí state; and finishing with the TL between the São João do Piauí substation and the Sobradinho substation in Bahia state, spanning a further 210 km. The line became operational in 2006 and the concession is to run for 30 years.

- ATE III Transmisora de Energía. ATE III, measuring 459 km, comprises the following TLs and substations:

- Itacaiúnas – Colinas at 500 kV.

- Itacaiúnas – Carajás at 230 kV.

- Itacaiúnas – Marabá at 500 kV.

The company was created to exploit and operate public concessions for the transmission of electrical power, encompassing the construction, implementation, operation and maintenance of basic grid transmission installations within the Brazilian interconnected electrical system. Abengoa was awarded the contract to construct and subsequently operate and maintain the Norte-Sur III 500 kV and 230 kV TLs and substations for a term of 30 years.

ATE III 230 kV transmission line crossing the river Araguaia (Brazil)

- ATE IV - São Mateus Transmisora de Energía. Aneel awarded Abengoa a contract for the construction and 30-year operation and maintenance of the following four TLs and substations:

- Bateias – Curitiba TL at 525 kV.

- Canoinhas – São Mateus TL at 230 kV.

Construction of this 85 km transmission line was essential for the power system of the metropolitan area of Curitiba, capital of Pará state, due to the huge local population and the heavy presence of industry within the region.

ATE IV Bateias substation - lines arriving from the Curitiba substation, Brazil.

- ATE V – Londrina Transmisora de Energía

Concession dedicated to exploit and operate public concessions for the transmission of electrical power, encompassing the construction, implementation, operation and maintenance of basic grid transmission installations within the Brazilian interconnected electrical system. Abengoa holds the concession to construct and subsequently operate and maintain the 230 kV TLs and substations for a 30-year term.

ATE V, spanning a total of 132 km, comprises the following sections:

-

230 kV Londrina – Maringá TL, located in the state of Pará and measuring 88 km.

-

Jaguaraíva – Itararé TL, also 230 kV, located in the states of Pará and São Paulo and spanning a total distance of 44 km.

- ATE VI – Campos Novos Transmisora de Energía

The concession from Aneel envisages the construction and 30-year operation and maintenance of the 230 kV TL and substations. This line upgrades the central electricity grid of the states of Santa Catarina and Rio Grande do Sul to boost economic growth within the region.

The TL covers a total distance of 131 km, and is divided into two sections: Campos Novos – Videira and Doña Francisca-Santa Maria.

-

The 230 kV Campos Novos – Videira TL, located in the state of Santa Catarina and covering 68 km;

-

and the Doña Francisca-Santa Maria TL, located in the state of Rio Grande do Sul, also 230 kV and spanning 63 km.

ATE VI Transmission tower for the ATE VI Campos Novos-Videira line (Brazil)

- ATE VII – Foz do Iguaçu Transmisora de Energía

The company was awarded the construction and 30-year operation and maintenance of the 230 kV Cascavel Oeste-Foz do Iguaçu TL and substations.

ATE VII comprises the 115 km Cascavel Oeste-Foz do Iguaçu TL and two substations, located in the state of Pará.

Peru

Despite having been general elections in Peru in 2011 and a complicated international climate, Abengoa continued to report growth in all lines of business, particularly in the power transmission lines market.

In 2011, the company focused its attention on the following activities:

-

Starting the operation and maintenance of the first sections of the Carhuamayo-Cajamarca TL (ATN).

-

Consolidate the skilled workforce of the concessionaire company.

-

Managing the corresponding easement and approving the environmental impact study for the proposed Chilca-Marcona TL (ATS).

Abengoa concessions can be broken down into the following two categories:

Public concessions

-

ATN: construction of the high-voltage 220 kV Carhuamayo-Cajamarca line and associated substations. The project envisages the design, supply and construction of the entire electrical system and operation and maintenance for a 30-year term.

The project involves 570 km of 220 kV line, two new substations and upgrades to five existing substations. The new infrastructure traverses the Peruvian mountains at an average elevation of 3,000 m above sea level, climbing to a maximum of 5,000 m. The project will benefit the northern reaches of Peru, specifically the provinces of Cerro de Pasco, Huanuco, Ancash, La Libertad and Cajamarca.

In 2011, the following sections of the line were brought into commercial service:

-

Section I – Carhuamayo-Paragsha TL: January 2011.

-

Section II – Paragsha-Conococha and upgrades to the Cajamarca substation: February 2011.

-

Section IV – Kiman Ayllu-Cajamarca: June 2011.

-

Section III - Conococha-Kiman Ayllu: December 2011

-

ATS: construction of the 500 kV Chilca-Marcona-Ocoña-Montalvo TL and associated substations, including the installation of two series compensation capacitors at the Ocoña substation. The project involves the design, supply and construction of the entire electrical system and operation and maintenance for a 30-year term, and comprises 872 km of 500 kV line and 28.5 km of 220 kV line, three new substations and upgrades to three existing substations. The resulting system has a transmission rating of 800 MW and 1,200 MVA of transformer power.

In 2011, the company continued to carry out the engineering work and preliminary studies, to seek licenses and permits, including formalities relating to the easement, and to conduct scoping and environmental impact studies to be able to commence construction. Assuming contractual timeframes are met, the project will be brought into commercial service in July of 2013.

Private concessions

-

ATN 1: construction of the 220 kV Paragsha-Francoise TL and upgrades to the Paragsha II and Nueva Francoise substations, including operation and maintenance for a 30-year term. The project embraces engineering work, studies, procurement and construction in relation to the roughly 55 km of high-voltage line, which will be strung at between 4,200 and 4,500 m above sea level within a timeframe of 540 days.

The corresponding contract was awarded in October 2010 and since then the engineering work and preliminary studies have been completed and the main supplies procured. As the public authorities (Ministry of Energy and Mines of Peru) have been late in approving the environmental impact study, there has been a delay in obtaining the necessary permits and licenses. Negotiations are therefore under way with the customer to extend the estimated term for completion by six months. The project is expected to enter commercial service in November of 2012.

-

ATN 2: this project involves the construction of the 220 kV Las Bambas-Cotaruse overhead line, as well as the 18-year operation and maintenance. The contract includes the engineering and study, procurement and construction of the roughly 130 km-long HV line within a timeframe of 780 days.

The concession was initially arranged through a memorandum of understanding signed in May 2011 and the parties are now negotiating the binding contracts. The project is expected to enter commercial service in July of 2013.

On a final note, and as a result of the forecast market growth for the region, there are a number of mining projects that are currently being explored or for which the relevant permits are being sought. These mines require a one-stop resolution to their long-term electrical power needs and given the experience that Abengoa has gained from the ATN and ATS projects and the synergies that can be created, the company intends to prepare and present one-stop solutions to satisfy the needs of these mining customers.

Chile

Abengoa is a key player within the Chilean electricity market and the company expects to report high growth from its projected investments for the coming years.

In energy, Chile has a vulnerable power transmission system that must be expanded to meet the needs and growth of the country. The aim is, in fact, to double Chile’s electricity generation capacity by the end of this decade, which would effectively mean installing over 8,000 MW of capacity from now until 2020.

Options on the table include interconnecting the north and central trunk systems, installing a second trunk transmission system, or constructing direct current lines to transport energy from the far south of the country to central Chile.

Investments in mining and electrical power projects are also of huge importance for the coming five years, and the company therefore expects an auspicious climate for order intake.

Shot of the Santa Bárbara Trupán TL at dusk (Chile)

Abengoa operates in Chile the following projects under concession:

- 1x220 kV Crucero – El Abra line: this 1995 concession comprises a 101 km power line that transmits 100 MW and which is currently in full operation.

- 2x220 kV Santa Bárbara – Trupán line: this 1994 concession consists of a 54 km double-circuit power line that transmits 300 MW and which is currently in full operation in southern Chile.

- 2x220 kV Ralco – Charrúa line: this concession, awarded in 2001, comprises a 140 km double-circuit power line that transmits 600 MW. The line is used to evacuate the power generated by the Ralco plant.

- 15, 66 and 220 kV Palmucho plant lines, Zona de Caída substation: this 2005 concession comprises a transformer substation and 10 km of 23 kV line, which transmits 32 MW to the Central Interconnected System.

All maintenance work on the infrastructure described above is carried out by Abengoa workers and the company duly meets all the availability ratios required by the different systems.

Solar power

Concessions at Abengoa are divided into the following lines of activity:

-

Development of CSP and photovoltaic power plants: this includes prospecting ideal locations for solar plants, carrying out the necessary administrative formalities to commence construction, negotiating project financing and construction agreements and, when needed, identifying potential partners and reaching agreements with them.In addition, Abengoa provides support during the engineering and turnkey construction of the plants.

-

Sale of power and plant operation: the solar power plants developed by Abengoa sell their electricity under long-term concessional agreements, meaning the optimum operation and maintenance of these facilities is key to future growth.

Solucar complex (Seville, Spain)

Abengoa’s portfolio of plants is classified according to the degree of maturity of development.

There are four project phases, which are typically classified as follows:

- Development: this chiefly includes site selection, securing of land and assessment of the solar resource; administrative formalities and obtaining licenses, permits and authorizations; ensuring the plant is connected to the grid and arranging the connection infrastructure.

-

Pre-construction/early stage: this phase includes the steps required to secure project financing for those plants which, as well as having land rights, permits, authorizations and licenses, also meet the relevant requirements entitling them to receive certain revenues (registration of the project in the pre-allocation register, or signing of energy purchase agreements, such as with local electricity utilities in the case of the United States). In this stage, construction activities are started

-

Construction: start of construction work on the facilities, oversight of engineering and construction work and processing of the relevant permits, as well as support in starting up the facilities.

-

Operation: this includes taking control of the plant following construction; the evacuation and sale of electrical power; and the operation, maintenance and exploitation of the plants.

Plants in operation

At the close of 2011, Abengoa held a total of 443 MW in operation. Over the course of 2011, the company gained further experience in operating the two main CSP technologies: power tower and parabolic-trough technologies.

Abengoa has improved its tower technology capabilities thanks to its four-plus years of experience in operating the PS10 plant, the world’s first commercial tower plant, and two-plus years of experience operating the PS20 plant with excellent results.

Focusing on parabolic-trough technology, the start-up of Helioenergy 1 and 2 at the Ecija solar complex has brought the company’s total portfolio to 250 MW in operation of this thermal power technology, complementing the three 50 MW plants at the Solucar complex, namely Solnova 1, 3 and 4.

In addition, the 150 MW Hassi R’Mel (Algeria) combined cycle power plant with solar field was brought online in 2011.

In photovoltaics, Abengoa is gaining experience from the 12 MW it currently has in operation, which are proving to be of immense value in the development of new technologies.

Each plant has its own characteristics and benefits, as described in further detail as follows

Solucar Complex

-

PS10

After successfully undergoing operational testing, PS10 was commissioned in June 2007 to become the world’s first commercial plant utilizing power tower technology. Located at the Solucar complex, the plant has an installed capacity of 11 MW and generates enough clean energy to satisfy the power needs of 5,500 households, while slashing annual CO2 emissions by 6,700 t.

PS10 was the first CSP plant to feature a storage system, enabling it to continue generating electricity for roughly an hour so that it can still produce power during cloudy spells or at the end of the day when solar radiation is insufficient.

Since its start-up, PS10 has matched expected performance levels and helped to prove the viability of tower technology on a commercial scale.

Solucar complex (Seville, Spain)

- PS20

PS20, which was commissioned back in February 2009, was only the second of its kind and the world’s largest power tower plant in operation at the time. The facility,which forms part of the Solucar complex, has an installed capacity of 20 MW and generates enough electricity to power 10,000 households, while curbing annual CO2 emissions by 12,100 t.

PS20 features a number of important technological advances, all developed by Abengoa, over the world’s first commercial power tower plant, PS10. These include a more efficient receiver and a raft of improvements to the control and operation systems and also the thermal energy storage system.

The technological improvements incorporated into the second plant, which have led to huge improvements in power tower technology, meant the plant successfully passed production testing with results comfortably outstripping predicted results, a pattern that has been validated over the nearly two years of operation of the plant.

This second plant comprises a solar field of over 1,255 heliostats designed by Abengoa, all of which focus solar radiation on a receiver located at the top of a 165 m tower.

-

Solnova 1, Solnova 3 and Solnova 4

Each of the three 50 MW plants generates enough electricity to power 25,700 homes while cutting annual CO2 emissions by approximately 31,400 t. The three plants started operating commercially in 2010.

After over a year in operation with exceptional results, they have more than proved their worth to the company and provide the basic blueprint for future plants currently under construction in Spain, the United States and Abu Dhabi.

These three facilities are the first of Abengoa to employ parabolic-trough technology and the first three of those included on the Spanish pre-assignment register to enter into operation.

Ecija solar complex

-

Helioenergy 1 and 2 *

The 50 MW Helioenergy 1 facility at the Ecija solar complex was commissioned in 2011, developed jointly by E.On and Abengoa, together with the 50 MW Helioenergy 2.

The plants mark a major milestone for both companies and underscore the commitment of both to developing solar power.

With over 88.000 employees, E.On is one of the major gas and electric companies.

It is the first complex to be started up by Abengoa with the involvement of an industrial partner. When both plants become fully operational, they will generate enough solar energy to power 104,000 households and help to curb annual CO2 emissions by 126,000 t.

* Helioenergy 2 has been effectively included in the Spanish government’s “Registro Administrativo de Instalaciones de Producción en Régimen Especial” (concessional type payments) after the closing of 2011. The effects of the registry started on the 1st of January 2012.

Helioenergy 1 and 2 in Ecija (Seville, Spain)

Hybrid integrated solar combined cycle (ISCC) plant in Algeria

The 150 MW facility, located in Hassi R’Mel, Algeria, comprises a combined cycle plant with 180,000 m2 of useful reflective area equivalent to 25 MW of thermal power.

Abengoa commissioned the project in 2011 alongside New Energy Algeria.

PV Plants

-

Sevilla PV

With an installed capacity of 1.2 MW, Seville PV was the world’s first commercial plant to employ low-concentration photovoltaic technology. It has 154 solar trackers on a plot of land occupying 12 hectares as part of the Solucar complex in Sanlúcar la Mayor.

The plant can supply clean energy to some 650 households, while curbing yearly CO2 emissions by over 1,800 t.

-

Copero PV

A 1 MW photovoltaic facility built on the grounds of the wastewater treatment plant (WWTP) that Emasesa operates at the El Copero site in Seville. Emasesa and Abengoa are joint 50 % owners of the plant.

-

Las Cabezas PV

A 5.7 MW photovoltaic plant with single-axis trackers located in an area of high solar radiation in the province of Seville.

-

Linares PV

A 1.9 MW photovoltaic plant with a dual axis tracking system located in Linares (Jaén). The area measures one of the highestin solar radiation in Andalucía.

-

Casaquemada PV

A 1.9 MW plant employing dual-axis photovoltaic tracking technology situated at the Solucar complex. The facility includes a 100 kW high-concentration installation featuring state-of-the-art technology.

Casaquemada PV (Seville, Spain)

Plants under construction

Abengoa has solar thermal power plants currently under construction in Spain, the United States and Abu Dhabi for a combined total installed capacity of 1,060 MW, in many cases in alliance with strategic partners.

In the United States, work is in progress on the Solana and Mojave plants, each with 280 MW of installed capacity.

In Spain, the company is currently constructing six 50 MW CSP plants; two on the El Carpio solar complex, two on the Extremadura solar complex and two on the Castilla-La Mancha solar complex.

In Abu Dhabi, work is continuing on the 100 MW Shams-1 plant.

El Carpio solar complex

In order to build and operate the two 50 MW parabolic-trough plants, Abengoa struck up an alliance with JGC, with Abengoa holding a 74 % stake in the venture.

Founded back in 1928, JGC Corporation has remained a leading engineering firm ever since. It currently offers a broad range of services in planning, design, engineering, construction and delivery of power, with a proven track record in more than 20,000 projects in over 70 countries worldwide.

Construction of both plants got under way in the summer of 2010 and is progressing well, with the facility scheduled to be commissioned during the first half of 2012.

Solacor 1 and 2 in El Carpio (Cordoba, Spain)

Extremadura solar complex

Abengoa and Itochu Corporation forged an alliance to construct two 50 MW CSP plants (Solaben 2 and Solaben 3) in Logrosan (Caceres). The company, which operates both plants, will retain control of the projects with a 70 % stake, while Itochu will own the remaining 30 %.

With approximately 150 offices in 74 countries, Itochu is a leading Japanese trading company operating commercially in the Japanese market, and also in imports and exports and international trade. It offers a wide range of products and services, including textiles, machinery, information and communication technologies, aeronautics, electronic goods, energy, metals, minerals, chemicals, forestry products, financing, real estate, insurance and logistical services.

Construction of both plants is advancing well and remains on schedule, with commercial operation expected to commence in 2012.

Other two plants (Solabén 1 and 6), listed in the pre-assignment register of the Spanish government, have obtained all permits required, having starded initial constuction activities such as earthwork and land elevation work. Arrangements for the supply of the main equipment have already been made and financing for the project is now in an advanced stage.

Castilla-La Mancha solar complex

Abengoa is building two 50 MW CSP power plants in the province of Ciudad Real (Castilla-La Mancha), both equipped with parabolic trough technology.

Project financing was secured in 2011 and construction is now well under way, according to scheduled commissioning. Start-up of commercial operation is expected in 2012.

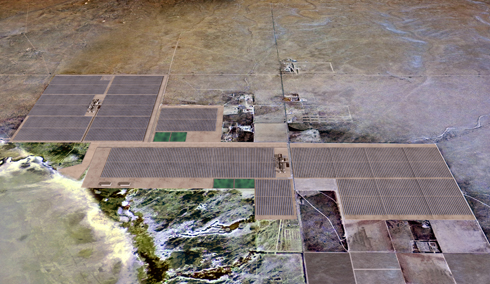

Solana

Solana, located 70 km southwest of Phoenix, Arizona, is one of the world’s largest CSP plants under construction, and will boast 280 MW of gross installed capacity (250 MW net) through cutting-edge parabolic-trough technology. Solana will generate enough energy to power 70,000 US households, while cutting yearly CO2 emissions by 475,000 t. The resulting power will be sold to APS, the largest electric utility in the state of Arizona, through a 25-year power purchase agreement.

Solana will include six hours of storage through molten salt technology, enabling it to store energy during cloudy spells and after sunset. This storage capacity will allow Solana to generate enough electricity to meet peak evening demand during the Arizona summertime.

Solana (Gila Bend, Arizona, United State)

At year-end 2011, work on the plant was under way and progressing well, having started the installation of the troughs.

The construction and operation of Solana will bring with it huge benefits, including the creation of between 1,600 and 1,700 jobs during construction and 85 permanent positions for the plant’s operation and maintenance.

Mojave

This project stemmed from the signing of a contract with Pacific Gas & Electric (PG&E) to supply the electricity to be generated at the new Mojave Solar plant, boasting a gross capacity of 280 MW. The facility will be located 150 km northeast of Los Angeles and will create about 1,600 new jobs in the local area during its construction and 85 permanent positions to handle the associated operation and maintenance work.

In 2011, Abengoa obtained a federal loan guarantee from the US government and successfully secured the necessary financing for the project.

Various components of this groundbreaking parabolic-trough plant were designed by Abengoa itself and manufactured locally.

Construction has effectively started in 2011.

The project will provide a huge economic boost to the area by contributing significantly to California’s renewable energy targets, replacing fossil fuels with solar energy and other alternative sources to curb greenhouse gas emissions.

Mojave Solar (Mojave Desert, California, United States)

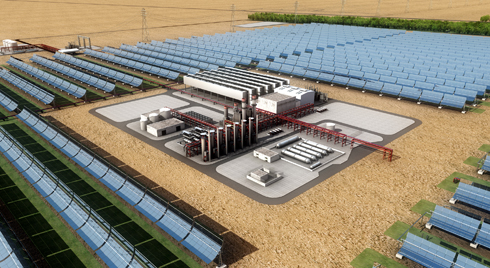

Shams-1, la mayor planta solar de Oriente Medio

A consortium comprising Abengoa and Total won an international tender to develop and operate, in joint venture with Masdar, the largest solar power plant in the Middle East. This first solar power project in the Middle East marks one of the first steps by the Abu Dhabi government to introduce renewable energy into a region which presently remains highly dependent on hydrocarbons. It also represents a strategic milestone for Abengoa due to the vast scope for development in the region.

Shams-1 (Abu Dhabi, United Arab Emirates)

The Shams-1 plant, construction of which started at the end of 2010, sits on roughly 300 ha of land in the Abu Dhabi desert and will have an installed capacity of 100 MW. The facility will include close to 600,000 m2 of ASTRØ parabolic troughs designed by Abengoa.

Shams-1 employs cutting-edge parabolic trough technology. Of the plant’s many innovative features, we would highlight its dry cooling system and its ancillary heating boiler. The dry cooling system reduces water consumption at the plant considerably, while the ancillary boiler heats the steam as it enters the turbine, notably boosting the efficiency of the cycle. Both features place Shams-1 at the very forefront of parabolic trough technology.

Construction is progressing according to plan and the plant is due to enter service during the second half of 2012.

Plants in pre-construction/advanced development

Abengoa has been awarded the first two CSP projects in the country by the South African Department of Energy.

KaXu Solar One

The South African Department of Energy has selected Abengoa to construct a 100 MW parabolic-trough solar plant.

KaXu Solar One, a 100 MW solar power plant employing parabolic-trough technology, will have a thermal storage capacity of 3 hours and will sit on 1,100 ha of land close to the city of Pofadder, in the north of the Northern Cape province. Around 800 jobs will be created during the construction phase, while 35 permanent jobs will be required for the subsequent operation and maintenance. The project will also create in the region of 200 direct or indirect jobs within the local community. The facility makes a hugely important technological advance by utilizing dry cooling systems.

The venture is owned by Abengoa, with a 51 % stake, and Industrial Development Corporation (IDC), with a 49 % share.

IDC is South Africa’s largest financial development institution and has helped to drive forward the industry on the path to ensuring economic growth within the country.

Khi Solar One

The second project for which the South African Department of Energy has selected Abengoa is a 50 MW plant featuring superheated steam tower technology.

Khi Solar One (50 MW) is set to become Abengoa’s third commercial power tower plant and its first outside Spain. The facility, with two hours of thermal storage, marks a major technological step forward in terms of efficiency by using higher process temperatures and having a nominal capacity two and a half times higher than that of the previous power tower built by Abengoa in Andalusia. This is thanks to the new generation of superheated steam technology developed by Abengoa at its R&D centers. As the plant will utilize dry cooling systems, its water consumption is slashed by 80 %. The tower plant will be constructed on a 600-ha plot of land near Upington, also in the Northern Cape province. Roughly 600 jobs will be created during the construction stage, while a further 35 jobs will be required for the subsequent operation and maintenance of the plant.

The venture is owned by Abengoa, with a 51 % stake, and Industrial Development Corporation (IDC), with a 49 % share.

IDC is South Africa’s largest financial development institution and has helped to drive forward the industry on the path to ensuring economic growth within the country

Plants in development

Abengoa has a dedicated team of over 100 people working on plant development in Spain, the United States and the other markets in which the company operates. Over recent years, Abengoa has channeled much of its time and resources into developing solar power plants. As a result, it has a sizeable portfolio in different phases of development and embracing both CPS and photovoltaic technologies.

Spain

Abengoa owns more than 1,000 MW in development in CSP plants in different autonomous regions. Most of these plants will be built following the introduction of the new regulatory framework in 2014.

United States

Abengoa has had a team of experts working on plant development since 2006, enabling the company to launch its two groundbreaking facilities in Arizona and California.

In addition to these Solana and Mojave plants, the company currently has other projects in various phases of development, including both CSP and photovoltaic technologies.

International development

Outside Spain and the United States, Abengoa has teams capable of offering the best possible solution to every possible need in those markets considered attractive due to their high levels of solar radiation and regulatory control. The company currently has various projects under different phases of development in both CSP and photovoltaic technologies.

Desalination

Desalination business is divided into three areas:

-

Development of water treatment plants, including membrane technology, requiring to invest in the facilities and oversee their design and construction.

-

Operation and maintenance and sale of water from the same plants or from plants owned by third parties under long-term concession agreements.

-

Development of new technologies through its R&D&I department.

Project development

Algeria

Abengoa presently has three concession contracts in Algeria with the state-owned company Algerian Energy Company (AEC):

-

Skikda: 2011 marked the second year of service with the plant operating at 100 % capacity. The facility was the first concession to be awarded in Algeria.

-

Honaine: this desalination plant is largest facility in terms of capacity that Abengoa will operate. It can produce in the region of 200,000 m3 of desalinated water per day and supply close to one million people.

-

Ténès: also boasting a capacity of 200,000 m3/day, this is the first desalination plant that Abengoa will build in its entirety. It is currently under construction, with operation and maintenance due to commence in 2012.

Honaine desalination plant (200,000 m3/day)

India

In July 2005, the company signed a financing agreement for the Chennai desalination plant located in the province of Minjur, in southeast India. The arrangement was reached with the Chennai Metropolitan Water Supply and Sewerage Board (CMWSSB), a public company from the country’s fourth largest city, which is also known as Madras. The contract follows a project finance DBOOT (Design, Build, Own, Operate, Transfer) model, with the facility to be the first plant to be developed under this model in India. Total investment for the project exceeds €100 M.

The sale of water fit for human consumption has been arranged under a 25-year concession. The desalination plant, with a 100,000 m3/day capacity, entered into operation and maintenance in July 2010 and has been performing in line with expectations ever since. The facility employs reverse osmosis membrane desalination technology, with pretreatment by flocculation, lameller settling, chemical filtration and treatment, post-treatment by remineralization, and energy exchangers. The design and construction of the plant proved to be a genuine challenge due to high salinity, strong tides and the monsoon season, all of which complicated working conditions.

Shot of the Chennai desalination plant (100,000 m3/day) in production since July 2010

China

Located in one of China’s most important ports in Shandong province, the Qingdao desalination plant currently under construction has been designed with a capacity of 100,000 m3/day and will supply drinking water to 500,000 of the 7.6 million population of Qingdao.

The resulting water will be supplied to Qingdao Highren Water Supply Group, a public corporation attached directly to the municipal government of Qingdao. The contract envisages the design, financing, construction, operation and maintenance of the facility for a 25-year term. It is the first contract to be signed exclusively with local Chinese banks, which will finance 70 % of the total investment, equivalent to roughly €135 M.

It features a groundbreaking design both for pretreatment (ultrafiltration membranes) and the centralized pumping system, thus helping to boost energy efficiency.

Commissioning and commencement of operation and maintenance is scheduled for the middle of 2012.

Qingdao desalination plant (100,000 m3/day)

Ghana

The most recent contract secured by Abengoa is a concession for the Nungua desalination plant located on the outskirts of the country’s capital city, Accra. The contract has been signed with the public company Ghana Water Company Limited. Total project financing of $110 M will be closed in early 2012 so construction period can be started after.

The proposed 60,000 m3/day capacity desalination plant represents a major step forward on the path to improving the hydro facilities for the supply of drinking water within the country, whose population is experiencing heavy growth. The capital city, Accra, with a population of roughly three million, is finding it difficult to cope with the demand of surrounding towns and villages. The new plant will help to supply water to nearby towns and cities such as Teshie Nungua and Tema.

Plants in operation and maintenance

In addition to the Skikda and Chennai plants described above, Abengoa has three operation and maintenance agreements in effect in Spain:

-

Almeria: the Almeria desalination plant, with a capacity of 50,000 m3/day, has been in service since 2005. The water it produces is supplied to the city of Almeria for human consumption and the operation and maintenance agreement is for 15 years.

-

Cartagena: with a total capacity of 65,000 m3/day and employing reverse osmosis technology, the plant, located in the province of Murcia, has been operational since the middle of 2005. Total project investment exceeds €55 M and the plant will be operated for a 15-year term. The membranes have been changed to boost the nominal capacity of the plant to 110 % of its original capacity.

-

Bajo Almanzora: the desalination plant, located in the province of Almeria, was unveiled in September of 2011, with the operation and maintenance phase due to commence at the start of 2012. The facility has a pre-design capacity of 60,000 m³/day and entailed a total investment of €73 M. The plant will be operated for a 15-year term, as with the other two plants. The facility also features a number of medium-voltage frequency converters, which increase the profitability of the plant while reducing energy consumption.

Abengoa can therefore produce a grand total of over half a million cubic meters of desalinated water per day.

Shot of the Almeria desalination plant (50,000 m3/day

R&D&I

Abengoa has a strategy centered on the development of proprietary technologies in the desalination area. It has a 3,000 m2 R&D&I center at its disposal, where over 40 researchers work, including seven doctorate holders and experts in membrane technology, desalination processes and water treatment. The center offers state-of-the-art facilities, including laboratories, exhibition hall, experimentation areas and a control room, allowing the company to optimize and streamline the running of our operational plants via satellite connection.

The company is currently developing four R&D&I programs:

-

Desalination program, which focuses on improving the efficiency of the reverse osmosis process while lowering associated investment, operation and maintenance costs.

-

The Potabilization-Purification-Reuse program seeks to optimize membrane-based water treatment processes so as to save energy and produce less sludge, and to develop sludge treatment and elimination technologies, such as supercritical oxidation.

-

Filtration membrane program, which focuses on the development of proprietary technology applied to seawater or brackish water desalination pretreatment processes; water filtration for potable use and urban and industrial wastewater treatment for water regeneration and reuse.

-

Sustainability program, through which the company is developing new solutions that incorporate renewable energy sources into desalination processes.

Inside a pilot plant

Abengoa’s main investment in desalination has therefore been in its R&D&I programs, which are key to the future growth of the company. It’s also worth noting that previously committed funds were effectively invested in the companies handling the projects under concession in Algeria, India and China.

Abengoa also completed the purchase of the remaining 49 % equity stake in the Texan company NRS Consulting Engineers, in which it has held a majority stake since October 2008. The full acquisition of NRS has helped to create synergies between Abengoa and its subsidiary by fusing the capacities and experience of both companies.

Cogeneration and other concessions

Cogeneration concessions

This section includes the company’s main cogeneration plants by country:

Spain

-

Aprofursa, Covisa and Enernova power plants

These plants generate electrical power while utilizing the resulting heat to produce water or steam. The electrical power is sold to the host industry or transmitted to the grid (market or tariff option), while the heat is used by the host industry. This kind of activity requires long-term power purchase agreements with the host industries, fuel purchase arrangements and plant operation and maintenance contracts.

Detailed below are the main characteristics of each plant: -

Aprofusa

This plant, located in Alcantarilla (Murcia), has a power output of 12.7 MW and employs a dual Deutz motor configuration.

The facility uses a heat recovery boiler to superheat exhaust gases from the diesel turbines before transferring the heat to the host factory, and generating electricity to be sold to the grid.

-

Covisa

This plant, situated in Cuevas de Almanzora (Almeria), has an installed capacity of 20.7 MW and employs a set-up comprising two Wärtsilä engines.

The facility utilizes the exhaust gases from the two engines to generate saturated steam and hot water in a heat recovery boiler. The heat dissipated by the engine cooling circuits is used to desalinate the water that feeds the host factory.

Wartsila engine room at Covisa

-

Enernova

This combined cycle plant, which features a LM1600 General Electric gas turbine and an Allen steam turbine, has an installed capacity of 19.6 MW and is situated in Ayamonte (Huelva).

The exhaust gases from a gas turbine generator are used to generate superheated steam in a heat recovery boiler for expansion in a steam turbine, generating electricity and thermal heat as hot water for use at the fish farm.

-

Procesos Ecológicos Vilches

Specialized in the recycling of livestock waste to produce fertilizer and electrical power through a slurry treatment plant (pig waste, mixed excrement, urine, water, leftover animal feed and other foreign bodies) combined with a electrical power cogeneration plant.

Although its contribution to the cogeneration business (approximately 380 MW) is relatively little, what impresses is the fact that it eliminates excess slurry, for which there is currently no other environmentally and economically viable alternative.

Business takes place in the municipality of Vilches, in the north of the province of Jaen in Andalusia. Future investments will focus on improving energy efficiency and environmental protection.

Mexico

-

Abengoa Cogeneración Tabasco (ACT)

ACT is a concession engaged in efficient electricity generation, as defined by the Mexican Energy Regulation Commission (Comisión Reguladora de Energía de México). This involves producing electrical power and high-pressure steam by burning natural gas and using the resulting combustion gases to generate high-pressure superheated steam.

The company is chiefly involved in the following lines of business: -

Generating 277 MWh of electrical power to be used at various plants belonging to Petróleos Mexicanos (Pemex) and to be transported to consumer connection points by the distribution grid of the Mexican Electricity Commission (CFE).

-

With the combustion gases, steam is generated and delivered (up to 800 t/h) at the Nuevo Pemex gas processing complex, owned by Pemex Gas y Petroquímica Básica, a Pemex subsidiary, and located in the municipality of Villahermosa, state of Tabasco.

The cogeneration facility is structured into two separate phases: the construction phase, which in turn comprises five stages before the plant enters service, and the operation and service delivery and acceptance phase.

Other concessions

This section provides a description of Abengoa concessions other than cogeneration assets, including dams and smart buildings:

Spain

The company operates in the following sectors:

-

Smart buildings (courthouses, penitentiaries, cultural centers, etc.).

-

Hospitals.

-

Rail transport.

-

Power transmission lines.

-

Renewable energies (photovoltaic plants, wind farms, ocean wave and tide facilities, etc.).

-

Energy efficiency.

The following are prime examples of these kinds of concessions:

-

Hospital Costa del Sol: the contract envisages the 40-year exploitation of the hospital building and underground parking lot. The hospital building has a floor area of 31,200 m2, while the parking lot occupies 25,500 m2 (960 spaces).

-

Hospital del Tajo: the contract envisages the exploitation (management and maintenance) of the hospital for a 30-year term. Gross surface area totals 58,000 m2.

-

Courthouses: Abengoa owns surface rights to construct and maintain the courthouses at Olot, Cerdanyola and Santa Coloma de Gramanet, and to operate the buildings through a lease with the regional government of Catalonia. Olot courthouse (Gerona) has a gross floor area of 3,376 m2, while the courthouse at Cerdanyola del Vallés (Barcelona) has 8,288 m2 and the one at Santa Coloma de Gramanet (Barcelona) 7,559 m2.

-

Irrigation zone of the Navarra Canal: this concession involves exploiting the infrastructure of the irrigation zone of the Navarra Canal in relation to phase one, meaning up to the river Aragon, a tributary of the River Ebro, spanning 23,611 hm. This phase will provide service to over 6,600 irrigation subscribers from 27 municipalities, thus guaranteeing high-quality irrigation water, paving the way for a rich variety of crops and improving the competitiveness of the agricultural sector.

-

Cerrato hydro power station on the Pisuerga river, Palencia: this run-of-river hydro facility can handle a flow rate of 70 m3/s through two 2,030 kVA Kaplan turbines and a further turbine that operates an environmental flow of 7 m3/s. The center has a total installed capacity of 4 MW

Cerrato hydro power station on the Pisuerga river, Palencia

-

Mini-stations along the Aragon and Catalonia irrigation canal: these stations were built to harness the hydro power of eleven rapids on a stretch of the canal as it passes through the provinces of Lerida and Huesca. At each site, the canal has been widened to allow for the construction of a parallel canal or channel to the right in order to feed the mini hydro station. After driving the turbine, the flow is fed back into the canal at the end of the rapid. The eleven stations have a combined power output of 7 MW.

Mexico

-

Centro Cultural Mexiquense de Oriente (CCMO) cultural center

Boasting a gross floor area of 35,000 m2 and sitting on a 17 ha. plot of land, the center will welcome over six million local inhabitants. Its avant-garde design makes it an unmistakable local landmark with the stunning views of the Texcoco valley and the surrounding area as its backdrop.

The complex includes 8,500 m2 of museums, libraries, workshop modules with over 60 classrooms intended for a range of different art-related subjects, an administrative building, auditoriums, an open-air theater, a concert hall with seating for 1,200 people, a cafeteria, a restaurant and enough parking for over 1,000 vehicles.

The customer is the Mexican Institute for Culture (Instituto Mexiquense de Cultura, IMC) and Abengoa has been entrusted with the operation of the center for 20 years. After this, the building will be handed back to the IMC in accordance with the terms of the applicable framework (projects to provide services). The buildings are fitted with cutting-edge technology to ensure optimum functioning, including the use of photovoltaic cells to generate enough power to illuminate the parking area.

-

El Zapotillo aqueduct

The Mexican Water Commission (Conagua) has chosen Abengoa to build the El Zapotillo aqueduct, which will provide an efficient, sustainable and secure means of supplying drinking water to nearly one and a half million inhabitants. The proposed El Zapotillo – Los Altos de Jalisco – León Guanajuato aqueduct (Mexico) will draw water from the El Zapotillo dam and feed it to the city of León and the municipalities of Los Altos de Jalisco.

The engineering work includes the construction of 139 km of large diameter piping; pumping stations with a total installed capacity of 24,000 kW; a drinking water treatment plant of 3,800 L/s; a storage tank capable of holding 100,000 m3 and a 40 km distribution circuit within the municipality of León. All to purify and transport a maximum of 5,600 L/s, of which 3,800 L will be channeled to the city of León, in Guanajuato, and the rest to the municipalities of Jalisco state.

Abengoa has been tasked with the engineering, construction, outfitting, operation and maintenance of the infrastructure. The company will operate the concession for 25 years: 3 years to start it up and the remaining 22 for operation and maintenance. Estimated revenue for the operating period exceeds $800 M.

Uruguay

-

Palmatir

Construction and exploitation of the Peralta wind farm (50 MW) in Peralta, Tacuarembó (Uruguay). The farm is to be built at the start of next year, before then moving on to the operational phase.

Brazil

-

Wind farms

Secured contracts from Aneel (Brazilian Electrical Energy Agency) for three wind farms with a combined capacity of 64 MW, namely Santo Antonio Pádua, Sâo Jorge

and Sâo Cristovâo, all located in the municipality of Trairí in Ceará state (Brazil). Construction is scheduled to get under way in 2012 and Abengoa has been entrusted with the subsequent operation of the facilities.

ATE II. Torres de la LT en 500 kV de ATE II Ribeiro Gonçalves (Piauí) – São João do Piauí (Brasil)

ATE V Torre de transmisión para la línea ATE V de 230 kV Londrina – Maringa (Brasil)

Carhuamayo - Cajamarca ATN TL concession (Peru)

L3 – TL concession, Carhuamayo, Paragsha, Conococha, Huallanca, Cajamarca, Cerro Corona, Carhuaquero 220 kV TL Conococha-Kiman Ayllu – L3 cable stringing process (Peru)

SPP-1 Hassi R’mel (Argelia)

Solaben 2 and 3 Logrosán (Cáceres, Spain)

Helios 1 and 2 Ciudad Real (Spain)

La ministra del Agua de Ghana visita las instalaciones de Abengoa en Sevilla

Enernova cogeneration plant in Ayamonte (Huelva)

Procesos Ecológicos Vilches Gas drying and treatment at PEV

Turbines for the Nuevo Pemex cogeneration plant in transit

Cerrato hydro power station on the Pisuerga river, (Palencia)

Mini hydro station sluice gate to keep water levels constant on the Aragon and Catalonia Canal.

Inside the CCMO theater

© 2011 Abengoa. All rights reserved