Abengoa

Abengoa

Annual Report 2011

- Activities

- Activities

- Industrial Production

- 2011 in Review

Biofuels

At present, Abengoa ranks as one of the leading biofuel producers in Europe, the United States and Brazil, with an annual production capacity of 3,175 ML.

The bioenergy business unit is currently reporting excellent levels of business, reflecting its standing as one of the world’s leading bioethanol producers and marketers. Production at existing plants is living up to the company’s full possibilities, and the forthcoming plant at Hugoton, United States, will further strengthen the company’s critical mass.

After ten years of developing technology to convert lignocellulosic biomass into fermentable sugars for subsequent processing into bioethanol, in September 2011 Abengoa started to build the world’s first commercial plant specified to process various agricultural wastes and energy crops into biofuels. With this milestone, after five years of implementing the various phases of the project, the company has proven its world leadership in this promising industry. The plant is expected to be fully operational within the first half of 2013. This will be the world’s first second-generation plant and the company’s seventh bioethanol plant in the United States, so bringing Abengoa’s total biofuel output in the US to over 1,500 ML.

There is now a clear need for a change of practices and policies and various governments have already begun to act accordingly. Business performance depends largely on favorable legislation that facilitates the development of new technologies while enabling biofuel culture to expand and combat the obvious signs of climate change.

Legislation aimed at combating climate change has been a key aspect on the agenda of the US government over 2009 and 2010. The main objective is to reduce the GHG emissions generated by the transportation fuel sector. The main act currently championing the development of the bioethanol sector, and underpinning the RFS (Renewable Fuel Standards) and the rules and regulations governing production and biofuel implementation requirements, is the Energy Independence and Security Act, which was approved in 2007 and enacted in 2010.

Two new legislative acts were enacted on June 25, 2009 in order to consolidate and kick-start the biofuel market over the coming ten-year horizon. European Directive 2008/28/EC on renewable energy sources dictates that at least 10 % of transportation fuel within EU member states must be produced from renewable energies by 2020. The amendments made to Directive 2009/30/EC on fuel quality include an additional incentive for using biofuels by ushering in a compulsory reduction in greenhouse gas emissions during gasoline and diesel life cycles between 2011 and 2010.

Abengoa has developed a sustainability certification standard, RED Bioenergy Sustainability Assurance (RBSA). Specified in accordance with the Renewable Energy Directive and adopted by the European Commission, the standard enables certification candidates to demonstrate compliance with the sustainability requirements under the Directive as regards any input material or production process, from agricultural production through to marketing of the biofuel, including industrial processing stages. The European Commission’s endorsement of RBSA certification is proof of the excellence of Abengoa’s sustainability and environmental conservation initiatives in its biofuel production processes.

On January 21, 2011, the Environmental Protection Agency (EPA) approved the use of 15 % ethanol (e15) blends in light motor vehicles manufactured in or after 2001. Various regulatory issues remain to be resolved for e15 to be permitted throughout the country, but this approval constitutes a major step forward for the ethanol industry by creating a market beyond 10 % blends.

Against this backdrop, Abengoa has managed to harness the existing legislative framework and the biofuel markets, and has likewise been able to roll out its expansion plans over 2011, reinforcing the bioethanol and biodiesel projects initiated in previous years in Europe, the United States and Brazil, as well as cogeneration projects in Brazil to increase the overall performance of the plants already operating within the country.

For Abengoa, 2011 was a year of growth, with a wealth of success stories reported in the United States, Europe and Brazil. All objectives were met, while exploring new paths to expansion and market penetration:

- Started construction on the world’s first second-generation (2G) commercial plant in Hugoton, Kansas, which uses lignocellulosic biomass to obtain sugars, which are then fermented into ethanol.

- Obtained federal loan guarantee worth $132.4 M from the US Department of Energy for construction of the Hugoton plant.

- Hugoton plant gained backing from the US Department of Agriculture (USDA) to increase availability of non-food crops for biofuel production.

- Commissioning with total loading of a plant in Portales, NM, capable of producing 115 ML of bioethanol annually.

- Operations firmly established at the Europoort, Rotterdam, Netherlands.

- Operations firmly established at the two cogeneration facilities in Brazil, with a combined installed capacity of 140 MW.

- Started expansion of sugar cane milling capacity at the São Luiz plant, boosted from 2.8 Mt to 3.5 Mt annually.

- Houston, Texas terminal storage capacity increased to 13 ML.

- Abengoa increased ethanol and DGS (distilled grain soluble) export activity by barge along the Mississippi and Ohio rivers.

- Increased direct DGS sales to global markets.

- Promoted and expanded a network of direct blend (e5, e10 and e85) biofuel service stations in Spain, which already boasts 30 distribution points and has distributed

900,000 L. - Reached agreement to sell 65,000 t of CO2 produced to Messer in France.

- Started scaling and commercial-scale pre-production of enzymes at the lignocellulosic biomass plant at Babilafuente, Salamanca.

- Completed Cenit I+DEA project after four years of work.

- Abengoa’s biofuels sustainability standard (RBSA) approved by the European Commission.

- 100 % of bioethanol deliveries supported by certification to Abengoa’s biofuels sustainability standard (RBSA).

- First sustainability certificate awarded to an agricultural production chain under Abengoa’s RBSA standard.

- Started construction of the Ecoalga project experimental plant.

- Launched the BIOFAT technology demonstration project to produce biofuels from micro algae.

- Staged the 10th World Biofuels Conference.

- Biomass seminar staged at the new Hugoton biomass plant.

- Abengoa’s Brazilian subsidiary certifies to SA 8000 international social accountability standard.

- Abengoa’s European trading subsidiary secured ISO 9001, ISO 14001 and OHSAS 18001 certification.

- Indiana and Illinois plants secured ISO 9001, ISO 14001 and OHSAS 18001 certification.

- ISO 14001 and OHSAS 18001 certification awarded for the cogeneration processes at the São Luiz and São João plants.

Recycling

In 2011 Abengoa maintained strong volumes across its various business units.

The steel waste recycling division treated a total of 633,118 dry tons (t) of iron and steel dust with zinc and other metals content, of which 544,460 t came from common steel manufacturing in Europe and Turkey, while the remaining 88,658 t were collected from the main stainless steel production centers in Europe and South Africa. In addition, 16,234 t of galvanization waste was recycled.

The company’s growth strategy of capacity increases and geographical expansion led to the construction of a Waelz Oxide washing plant in Gravelines, France, which will have a nominal annual treatment capacity of 100,000 t. The facility, scheduled to come online in the first half of 2012, will cover the production washing needs of the French and German Waelz plants.

Computer visualization of the future Waelz Oxide washing plant at Gravelines, France

Moreover, after obtaining an Integrated Environmental Authorization in April, in late 2011 urbanization work began at the site of the future steel dust recycling plant at Villafranca de los Barros (Badajoz), with capacity to process 110,000 t annually. Construction is scheduled for completion by mid-2013.

Permits were obtained for building a Waelz Oxide washing facility at the Port of Bilbao —the Gravelines project’s sister installation— which will purify the output of the Erandio and Extremadura plants.

In 2011, the aluminum recycling segment processed spent potlining (SPL) waste to provide large producers with a one-stop and hitherto unavailable definitive waste recovery solution.

Abengoa held its leading position in Spain’s industrial waste recycling sector, managing 768,202 t of industrial waste, 13 % of which corresponded to recycled industrial waste, versus10% last year.

In late 2011, commissioning work began on a new sulfur waste recovery plant, which will provide major environmental improvements in all fields. The facility is equipped with the latest and most efficient technologies, many of which qualify as best available techniques according to the applicable BREF.

The new facility at Bilbao Port in the Zierbena district (Biscay, Spain) will be able to treat 120,000 t of sulfur while producing 350,000 t of sulfuric acid and oleum, effectively meaning it will be able to generate roughly 90,000 MWh per year of electricity.

Aerial view of the new sulfur recovery plant in the Port of Bilbao (Zierbena, Spain)

In the industrial wastes segment in Latin America, Abengoa started up the country’s first commercial incinerator, which is capable of treating 800 t/year of inflammable and hospital waste. In Chile, work was completed on the second hazardous waste landfill site, which will be able to store 64,000 m3 of the material. In Mexico, Abengoa has secured a remediation project, entailing the management of over 25,000 t..

Hazardous waste landfill site in Antofagasta, Chile

Solar power

In 2011, Abengoa continued to showcase and consolidate its international leadership in the solar power sector, climbing to 443 MW in operation, 1,060 MW under construction and 150 MW at the pre-construction or advanced development stage; what is more, Abengoa started work on two innovative plants offering viable, efficient solutions going forward.

In Spain, at the Solucar complex, Abengoa continues to develop demonstration plantsfor various thermal and photovoltaic technologies, reinforcing its staus as a reference for the world.

Highlights were:

- The construction of the Solugas project, a pilot tower plant using hybrid solar/gas technology. This plant will go into operation in 2012. The purpose is to demonstrate the performance of the towers at high temperatures, using air as the heat transfer fluid ans a gas-cycle instead of the steam-cycle.

- The CRS Sales project,which is under construction and will come online in 2012, testing the engineering and manufacturing of the solar power receptor prototype that uses a mixture of molten salts as the heat transfer fluid.

- Other projects, improving the operational efficiency of the direct steam generation parabolic trough plant and the continual validation of the thermal storage technology with molten salts.

In the United States, research projects are underway such as the development of new heat transfer fluids (HTF) and the design of new parabolic trough technology structures.

Abengoa’s structure manufacturing plants have supplied parabolic trough collectors for the Ecija, El Carpio, Castilla-La Mancha and Extremadura solar complex plants in Spain, Shams-1 in Abu Dhabi, Hassi R’Mel in Algeria, and Ain Beni Mathar in Morocco. Structure supply has been started for the Solana plant in the United States.

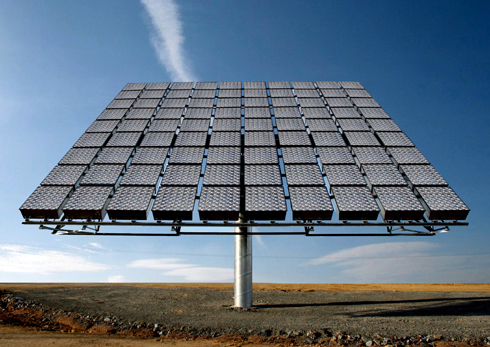

Throughout 2011, as a result of exclusive research and development completed by Abengoa over the course of several years, the high concentration photovoltaic (HCPV) module reached the market. This technology achieves 29 % efficiency.

In the field of industrial facilities, Abengoa has successfully designed and engineered the world’s largest industrial steam system. Located in Antofagasta, Chile, the plant will have a maximum capacity of 10 MW. The company also constructed a solar thermal plant, to supply hot water, on a plot of land lying adjacent to the Kraft Foods facilities in Brazil, along with a small demonstration plant at Red River College of Applied Arts, Science and Technology in Winnipeg, Canada, and two 40 kW rooftop photovoltaic systems at various premises of the company Cummins Power Generation in Fridley and Shoreview, Minnesota.

High-concentration photovoltaic (HCPV) module

Hydrogen, energy crops and ocean energy

Hydrogen business

Against the background of society’s increasing interest in renewable energy and environmental conservation, Abengoa’s research, development and innovation seeks to create new energy technologies based on the pairing of hydrogen and fuel cells. The company is therefore pursuing projects leading to concrete outcomes as to the technical and economic viability of hydrogen as a sustainable fuel.

A highlight project in 2011 was the continuation of the engineering and supply work for Navantia within the framework of the Air-Independent Propulsion System (AIP) for the S-80 submarines which the Navantia shipyard is constructing for the Spanish Navy. Over the year, the research division delivered the first units of the bioethanol processor (which uses this biofuel to produce hydrogen for the submersible), the power adjustment system (which adjusts the power produced by the fuel cell) and the AIP control system (which controls the functioning of all devices involved), and testing began on all three systems.

A particular highlight in December 2011 was the signing of an MoU (Memorandum of Understanding) and a collaboration agreement with the North American company FuelCell Energy, Inc. for the joint development of molten carbonate fuel cell technology and the construction of cogeneration plants based on these devices.

Energy crops

Research, development and innovation activities for biotechnology-supported biomass production are underway initially in Uruguay; they are set to start in Brazil shortly, and other countries are being considered for further expansion.

The unit aims to develop technological solutions that allow for productive and economic integration among:

- New, sustainably managed forest crops.

- Socially high-yielding afforestation and reforestation projects.

- (Existing and planned) biomass-based industrial plants.

- Global market in solid biofuels and cellulosic materials.

The expected contributions of research to the industrial value chain include:

- Steps prior to biomass processing, where the aim is to improve energy crop sustainability by emphasizing: characterizing the productive potential and fitness of biomass, securing sustainable supply for various industries, incorporating biotechnologies to production processes.

- Steps subsequent to biomass processing, where the aim is to develop technologies in support of identifying sustainable industrial bio-based products, with high potential for applications (process control, quality assurance, market positioning, etc.).

At year-end, Abengoa signed a contract with Schandy to operate the Montes del Plata lumber terminals at the cellulose plant currently under construction in Uruguay. The seven-year agreement is for $8 M a year and requires an investment in equipment and machinery approaching $20 M.

Ocean energy

In 2011, the ocean energy business emerged as one of Abengoa’s strategic undertakings for the coming years. Reaping the benefits of the installations business three years ago, Abengoa has strongly bolstered this division by assigning it increased human resources and funding and raising its profile as a first step of a long-term strategy.

EsIn this connection, it is worth highlighting:

- Cooperation agreement signed with the Irish company Wavebob Ltd. to research, develop and commercialize wave energy generation systems.

- Implementation of several lines of research —oscillating water column, point absorber, etc.— via various R&D programs.

- Abengoa coordinates the Ocean Energy Forum of the Spanish Maritime Technology Platform, alongside Iberdrola and APPA. In addition, Abengoa is the deputy chair of the Technical Committee for Electricity Production Standardization AEN/CTN206/SC114 “Ocean Energies: Waves and Currents Energy Converters”

- Abengoa is a member of the marine section of APPA (the Spanish association of renewable energy producers), the European Ocean Energy Association (EU-OEA) and OREC, the US Ocean Renewable Energy Coalition.

© 2011 Abengoa. All rights reserved